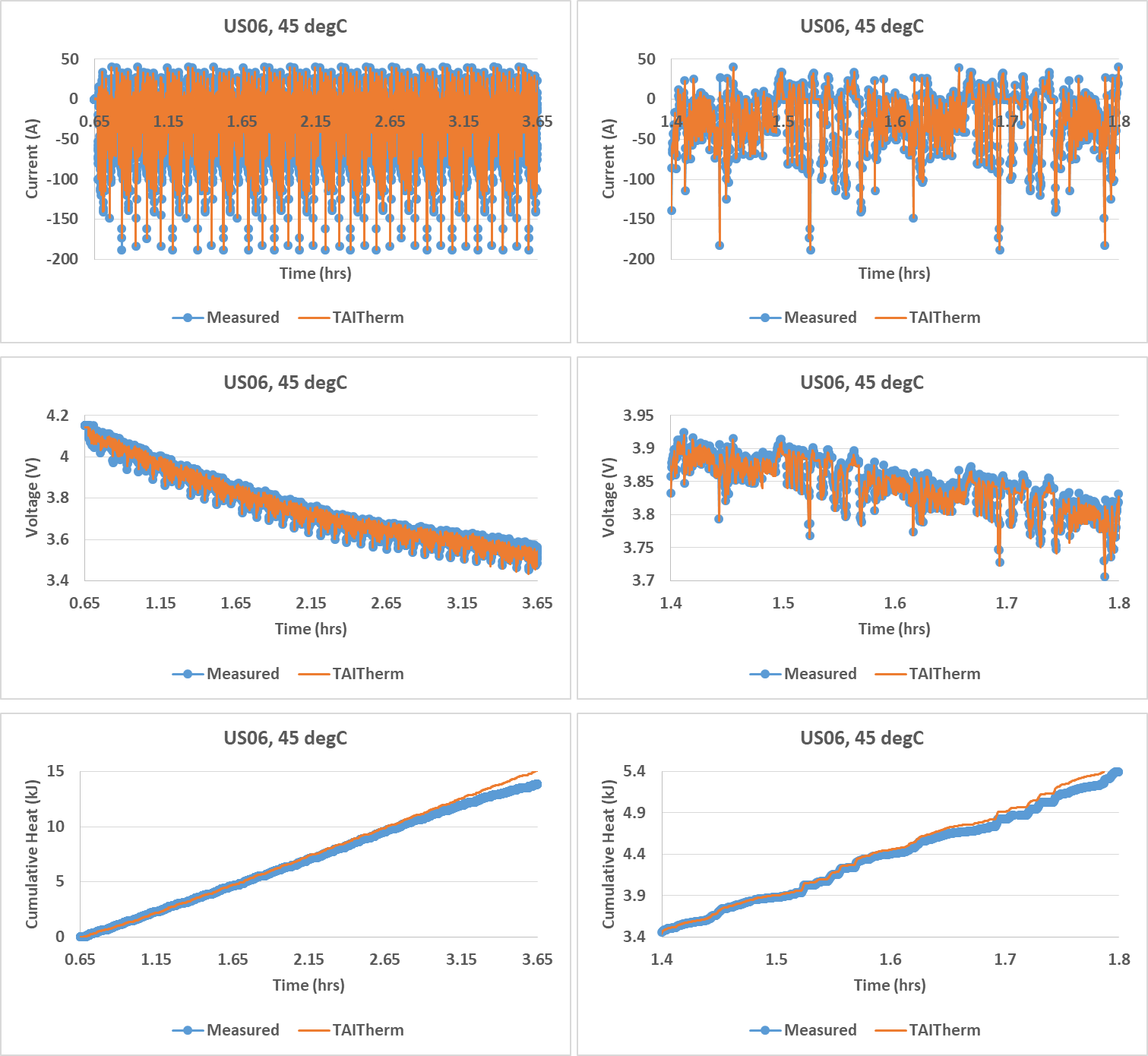

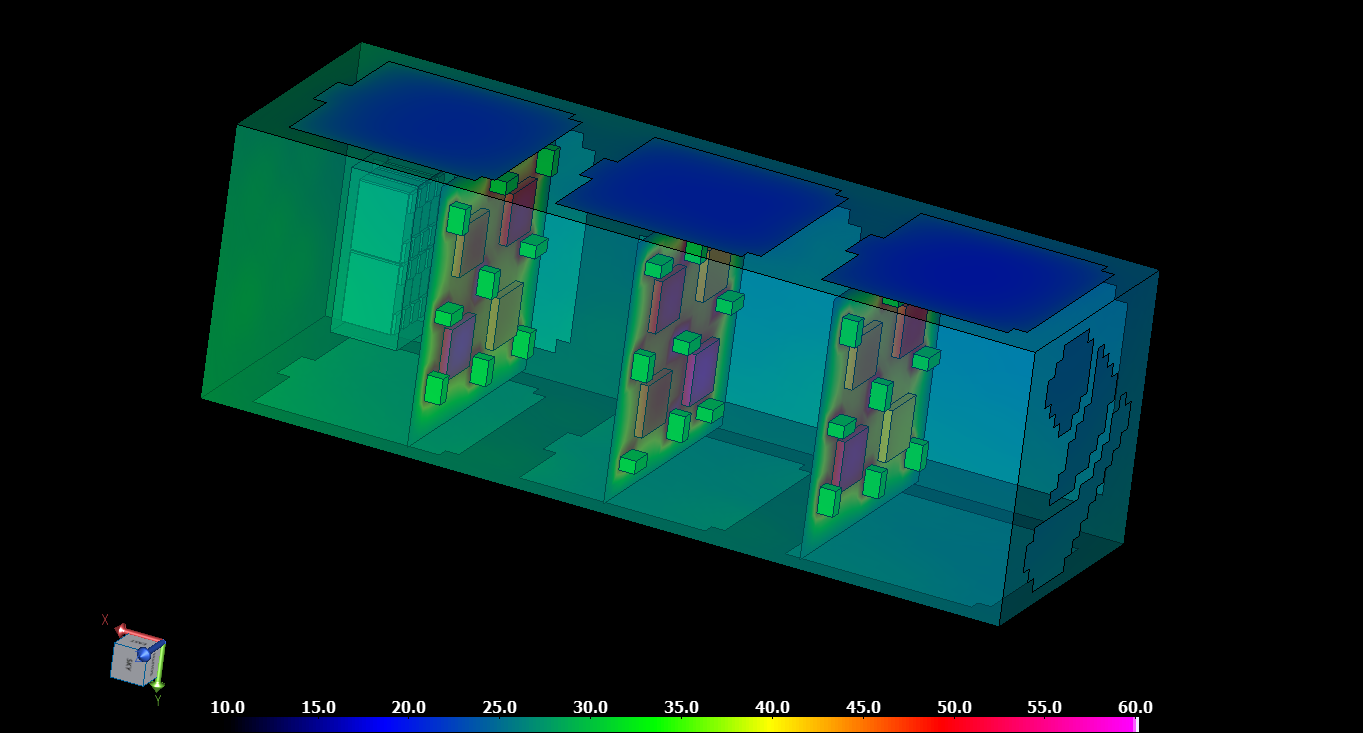

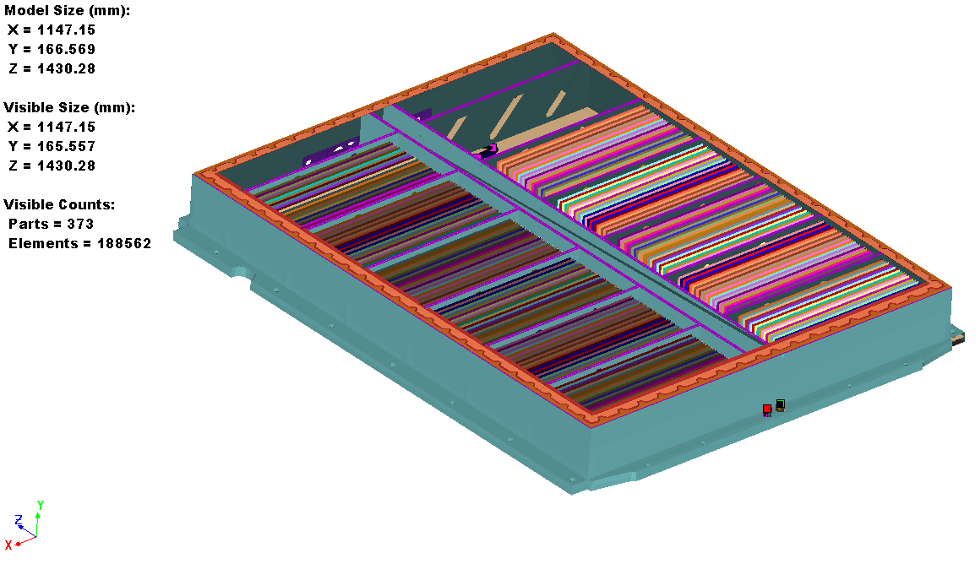

Energy storage systems (ESS) applications are plentiful as OEMs electrify their vehicle fleets, residential and commercial power demand turns toward...

Continue ReadingTopic: Thermal

Dynamic thermal and EO/IR satellite simulation with MuSES

By

Corey Packard on February 1, 2024

This blog will explore how dynamic satellite simulation performed with MuSES™ and CoTherm™ can predict in-orbit transient temperatures and generate...

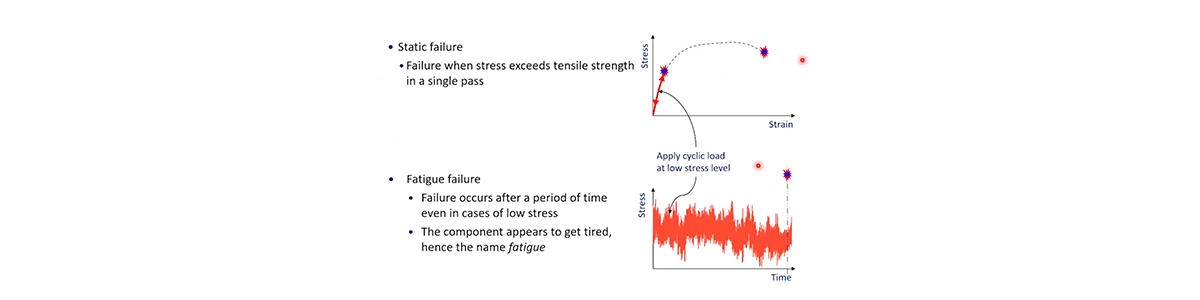

Continue ReadingPredicting & Evaluating Thermal Fatigue using TAITherm

By

Matt Monte on January 27, 2023

Introduction to Thermal Fatigue

Continue ReadingFast Charging Thermal Analysis Considerations for Electric Vehicle Design

By

Keith Kemp on July 7, 2021

Electric vehicle battery technology is moving forward rapidly, but the fundamental principles of battery performance clash with the fundamental...

Continue Reading

Submit a Comment