Electronics are increasingly central to system performance in automotive and high-tech applications. Components such as ECUs, ADAS cameras, and power...

Continue ReadingBoost Cabin Comfort & Efficiency with a 3-Tool Simulation Workflow

By

Deniz Hinz on October 23, 2025

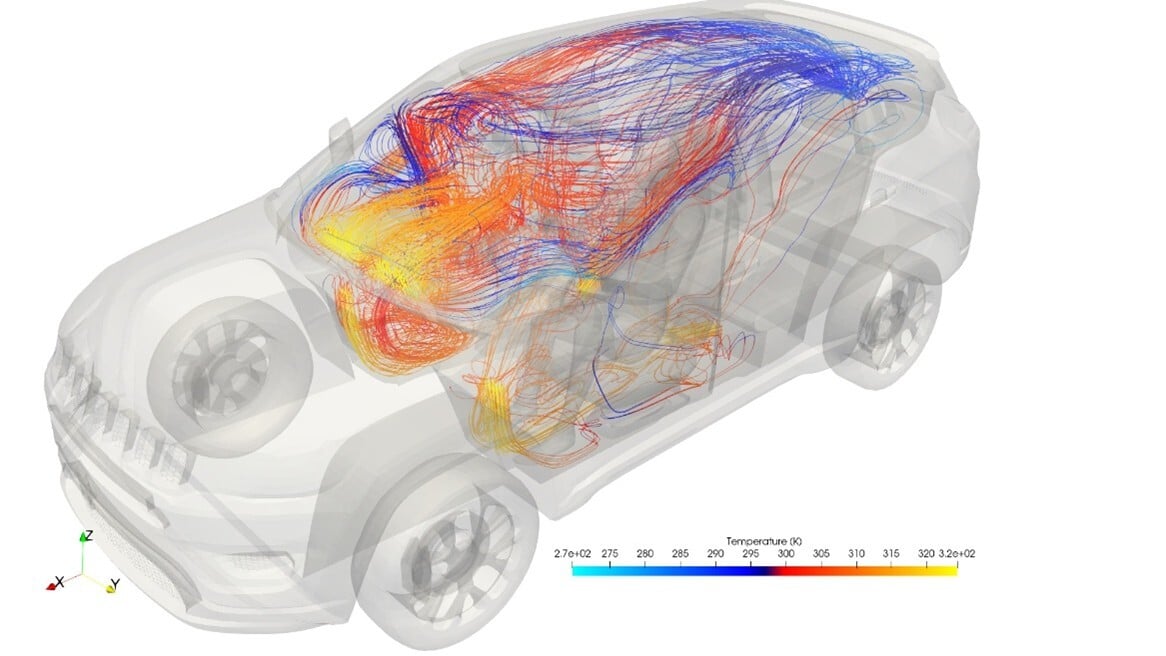

This blog will explore the application of a high-fidelity 3-tool coupling simulation workflow to the automotive cabin for energy and human thermal...

Continue ReadingThermoAnalytics 2025.2: Advancing Comfort, Accuracy, and IR Simulation

By

Steven Patterson on October 15, 2025

Version 2025.2 of TAITherm, CoTherm, and MuSES brings new capabilities that advance human thermal comfort, electrification, and defense simulation....

Continue ReadingRapidFlow: An Optimized Solver for Thermal Simulation in Cabin Analysis

By

Deniz Hinz on August 14, 2025

RapidFlow is a fast fluid solver designed for thermal simulation and is fully integrated into the TAITherm solver. It is optimized to reduce...

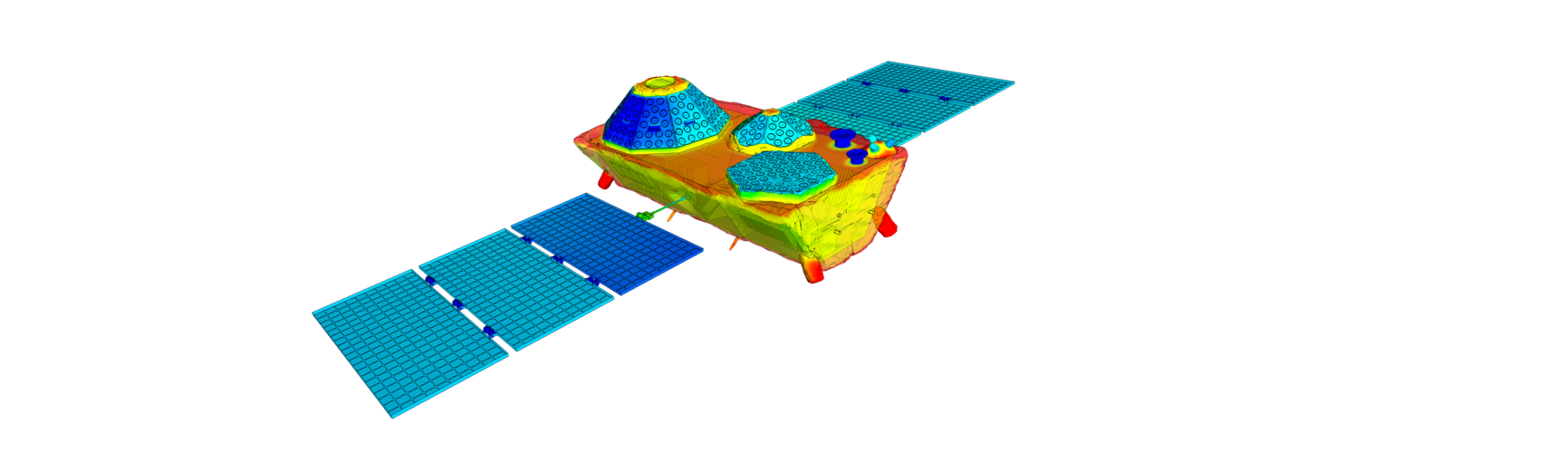

Continue ReadingDirected Energy Laser Weapons: Evaluating Impacts on Satellites through Thermal Simulation

By

Corey Packard on July 8, 2025

Directed energy weapons (DEW), particularly high-energy lasers (HELs), are rapidly evolving, posing a significant threat to space-based assets like...

Continue Reading

Submit a Comment