In this blog, we will give an overview of Cabin Comfort Thermal Analysis with TAITherm, OpenFOAM (OF), and FMI/FMU Coupling using CoTherm. TAITherm and CoTherm users benefit from tight integration with OpenFOAM, an open-source CFD toolbox. OpenFOAM has many advantages typical of open-source software such as a broad user base, tutorials, and example problems online. OpenFOAM has gained considerable credibility in recent years as a great tool for computational fluid dynamics, with a wide range of scientific/industrial interests. For this reason, OpenFOAM is one of the most widely used open-source CFD tools available.

The coupling workflow between TAITherm, OpenFOAM, and a 1D HVAC model (FMU) is capable of obtaining accurate thermal behavior predictions and objectively quantifying occupant comfort, while also incorporating HVAC component models. With OpenFOAM-based CFD solvers becoming more customary across the industry, ThermoAnalytics has developed a fully integrated solution to couple these tools.

This coupling offers the usability and accuracy of TAITherm for thermal modeling as well as the scalability and cost-efficiency of OpenFOAM for CFD analysis. By using CoTherm, these platforms are coupled seamlessly, offering OpenFOAM processes within CoTherm’s usable interface. With this process, both steady-state coupling and transient coupling scenarios can be applied.

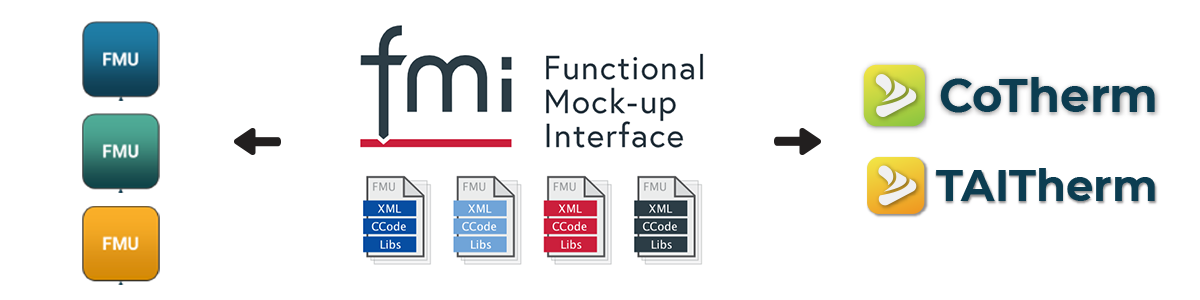

What is FMI/FMU?

FMI is an open standard that facilitates model coupling between a broad range of 1D/system simulation tools. FMI/FMU is a versatile coupling methodology capable of providing efficient, high-fidelity engineering solutions. A full list of simulation tools that support FMI/FMU can be found here: https://fmi-standard.org/tools/.

What is OpenFOAM?

OpenFOAM is the free, open-source CFD software developed primarily by OpenCFD Ltd since 2004. It has a large user base across most areas of engineering and science, from both commercial and academic organizations.

OpenFOAM has an extensive range of features to solve anything from complex fluid flows involving chemical reactions, turbulence, and heat transfer, to acoustics, solid mechanics, and electromagnetics.

FMU Import in TAITherm/Cotherm

FMU models exported from a third-party system/1D software can now be seamlessly coupled with TAITherm. Thermal/1D coupling allows the user to perform high-fidelity thermal simulations in TAITherm with realistic, dynamic conditions derived from complex component and system models. FMU system model coupling with TAITherm is a versatile technique to perform complex Multiphysics simulations efficiently and accurately.

FMU models can also be integrated as part of a larger CoTherm process rather than directly into TAITherm. As part of a CoTherm process, the FMU models can be coupled with additional 3D solvers, such as CFD. TAITherm FMU export is also a capability if desired.

Use Case: Cabin Thermal Comfort Simulation

Vehicle cabin thermal comfort along with a decrease in energy consumption present a major design challenge for modern car manufacturers. The expected increasing electrification of vehicles leads to reduced thermal energy potential in the vehicle. Lack of waste heat that is normally used for the cabin and battery heating means it takes a considerable amount of energy to cool or heat an entire cabin environment.

The mile range of an electric vehicle (EV) may be reduced significantly in colder weather owing to the energy demand for meeting thermal comfort in the vehicle cabin. Passenger comfort achieved through a localized thermal comfort strategy takes less energy than HVAC alone.

OEMs extending electric offerings also have several design objectives in mind for cabin thermal comfort simulation:

- Implementation of a climate controller and the impact on human comfort

- Reduce energy consumption

- Balance occupant comfort and vehicle range

- Shorten time-to-comfort

- Maintain comfort

Several simulation methods can assist you as you seek the optimal design solution. Picking a thermal simulation method can also be a bit of a balancing act as you choose between accuracy and reduced computational effort.

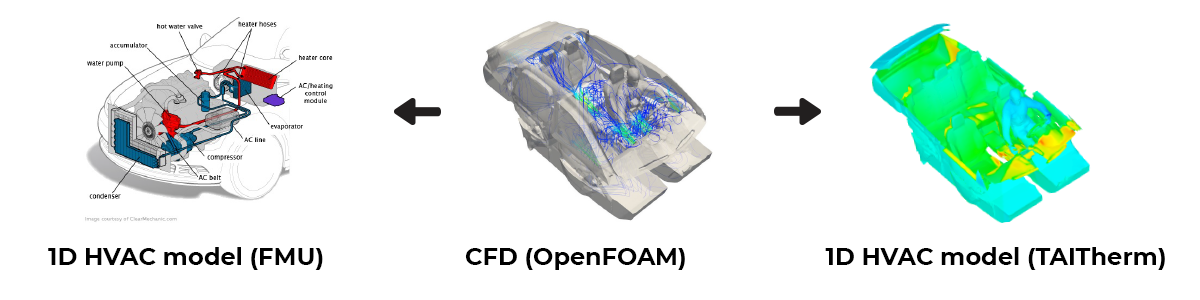

In this example case, the implementation of thermal-CFD-1D coupling is demonstrated in a cabin comfort application. The coupling workflow between TAITherm, OpenFOAM, and a 1D HVAC model (FMU) is capable of obtaining accurate thermal predictions and objectively quantifying occupant comfort, while also incorporating HVAC component models. The 1D HVAC model (FMU) provides detailed modeling capabilities for HVAC performance and control, therefore it is critical for energy management calculations.

A common thermal-CFD-1D coupling workflow is illustrated below:

The thermal solver, TAITherm, solves the cabin heat transfer problem, including conduction and radiation between vehicle components, solar load, and human physiology/comfort. TAITherm supplies the surface temperatures to the CFD solver, in this case, OpenFOAM. The CFD solver solves for the air velocity and temperature fields and supplies the convection boundary conditions to TAITherm. The FMU calculates HVAC performance and supplies vent air conditions to the CFD solver.

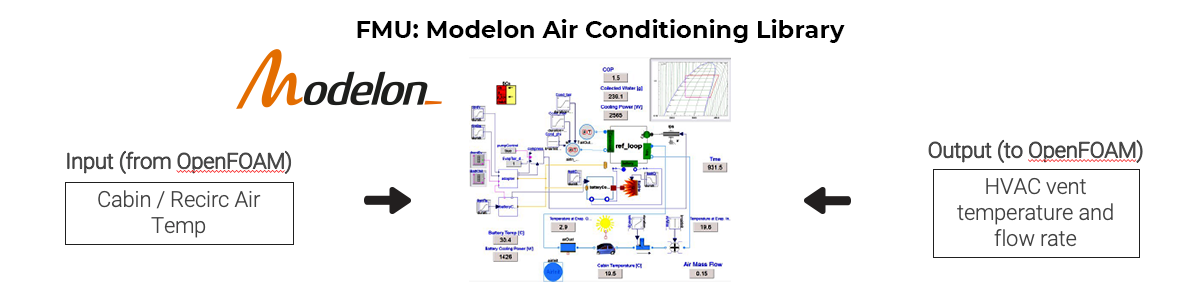

Working with FMU

Dymola system software was used to export an FMU of the Modelon Air Conditioning Library. In this case, a Co-Simulation FMU was exported, meaning the numerical solver was embedded in the FMU. The key input to the FMU was the cabin/return air temperature from OpenFOAM. The FMU then supplied OpenFOAM with the HVAC vent boundary conditions (air temperature and flow rate). CoTherm was used as the Master to facilitate the coupling between TAITherm, OpenFOAM, and the FMU.

Cooldown Scenarios:

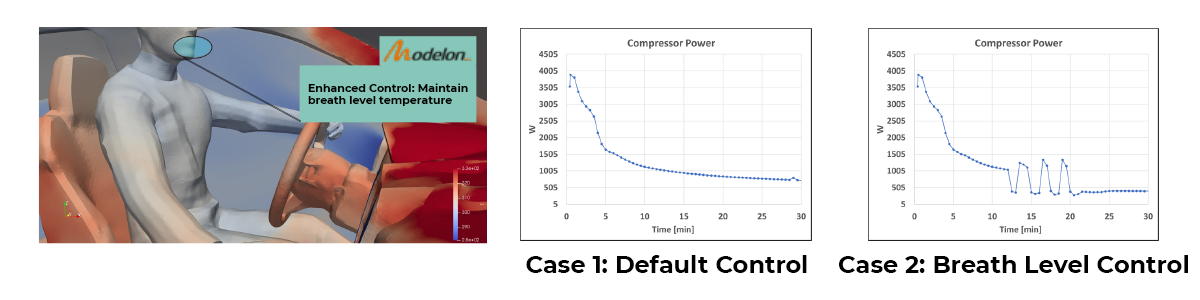

This example is a proof-of-concept demonstration of the implementation of a climate control system and its impact on human comfort. The default climate control scheme is improved to maintain occupant comfort by targeting a breath level temperature of

23 °C.

Two AC cooldown cases are compared:

1. Default control – Target evaporator air temp

2. Breath level temperature control – Target breath level temp

In both cases, the vehicle was initialized via a hot solar soak in a natural summer environment and the human was initialized in a comfortable office setting. The cooldown begins when the driver initiates a constant 30min drive cycle accompanied by an AC cooldown. The default AC cooldown case is comparable to a max AC cooldown scenario for 30 minutes. Compressor power for the default AC cooldown case can be found below.

For comparison, a breath level HVAC control scheme was implemented into the FMU for case 2. In this case, the climate controller is designed to maintain occupant comfort by holding a breath level temperature of 23 °C.

For comparison, a simple HVAC control scheme was implemented into the FMU for case 2. In this case, the climate control system is designed to maintain occupant comfort by holding a breath level temperature of 23 °C.

Vent/Cabin Temperature

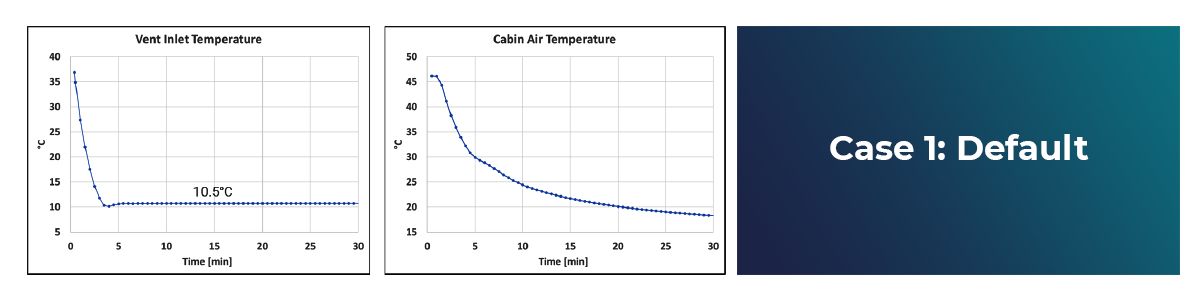

Average HVAC vent air temperature is plotted below for both the default and enhanced control AC cooldown scenarios. In the default case, the vent air quickly reaches a steady-state temperature of ~10.5 °C. Cabin air temperature continues to decrease for the remainder of the cooldown.

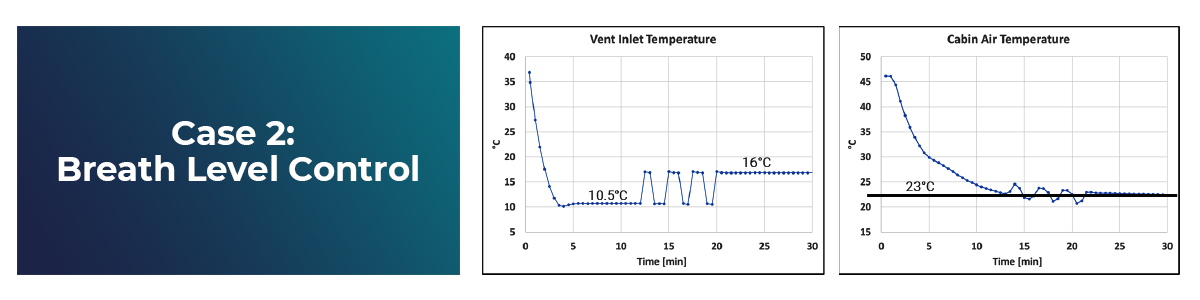

In the breath level temperature control case, the HVAC vent temperature begins to fluctuate between ~10.5 °C and ~16 °C when the breath level temperature nears 23 °C (at about 12 minutes). Eventually, the vent air temperature reaches a steady-state value of ~16 °C for the remainder of the cooldown.

Thermal Comfort

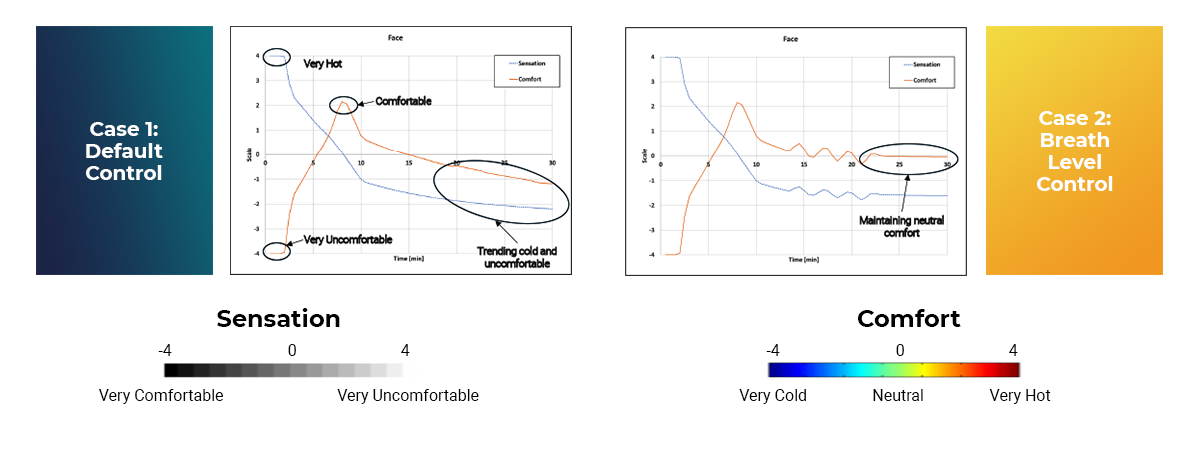

In simple terms, thermal sensation can be defined as the degree of feeling of “hot” or “cold”. Thermal comfort then defines to what degree the thermal sensation experienced can be deemed comfortable or pleasant. Thermal sensation and comfort analysis in TAITherm uses a 9-point scale. Sensation ranges from -4 (Very Cold) to 4 (Very Hot), where 0 denotes neutral sensation. Similarly, comfort ranges from -4 (Very Uncomfortable) to 4 (Very Comfortable), where 0 denotes neutral comfort. Sensation (blue) and comfort (orange) are plotted below as a function of time during the cooldown for both the default and breath level control cases.

In the default case, when the driver enters the vehicle, they first feel very hot and uncomfortable. As the vehicle rapidly cools, the driver attains a state of comfort at about the 8-minute mark. As time progresses, however, the driver’s comfort does not continue to improve. Rather, the driver trends toward discomfort as thermal sensation trends toward being too cold.

In the breath level temperature control case, sensation and comfort metrics are similar to the uncontrolled case for the first ~12 minutes. However, rather than trending towards discomfort from that point forward, the driver maintains sensation and comfort.

Conclusions

Thermal-CFD-1D coupling was demonstrated between TAITherm, OpenFOAM, and the Modelica AC system library in a cabin comfort application. The high-fidelity cabin coupling methodology provides the ability to obtain accurate cabin comfort predictions efficiently and with a comprehensive set of realistic simulation and boundary conditions.

By introducing the breath level climate control scheme in the AC system model FMU, the vehicle occupant was able to attain the same time-to-comfort but showed an improved ability to maintain comfort over the course of the cooldown. Additionally, by reducing the overall compressor load, the modified cooldown resulted in approximately 21.5% reduced total compressor energy consumption.

The FMI standard allows for tight integration of a wide array of 1D system tools with TAITherm. TAITherm offers industry-leading thermal analysis and thermal simulation solution capabilities for human comfort analysis and heat transfer in complex 3D geometries. With OpenFOAM integration, the user gains direct access to a highly customizable, cost-effective, and scalable CFD solver for convection solutions. Using CoTherm, the coupling between thermal, CFD, and 1D system models can be seamlessly facilitated, providing the user with powerful Multiphysics simulation capabilities.

There is a growing need for high-fidelity Multiphysics coupling capabilities across many industries in order to compute key performance metrics efficiently and with increased accuracy. For example, in the transportation industry, the accurate computation of HVAC performance and energy consumption are key metrics to determine the optimal balance between electric vehicle range and occupant comfort. Both time to comfort and the ability to maintain comfort must be analyzed under a wide array of operating conditions. These comfort metrics must then be balanced with HVAC and battery energy consumption to optimize EV range.

We at ThermoAnalytics are here to tailor our advanced numerical solutions to improve your simulation workflows. If you want to advance your simulation and high-fidelity coupling capabilities with TAITherm and CoTherm, please contact our technical sales team.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: