Space Domain Awareness (SDA) is critical in today's increasingly congested and contested space environment. While traditional visible and short-wave...

Continue ReadingDesigning a Micro-Climate Comfort Based Control System for Electric Vehicle HVAC Optimization

By

Deniz Hinz on June 3, 2025

This blog post is a summary of a technical webinar presented in conjunction with Gamma Technologies for SAE Tech Briefs. Increasing electrification...

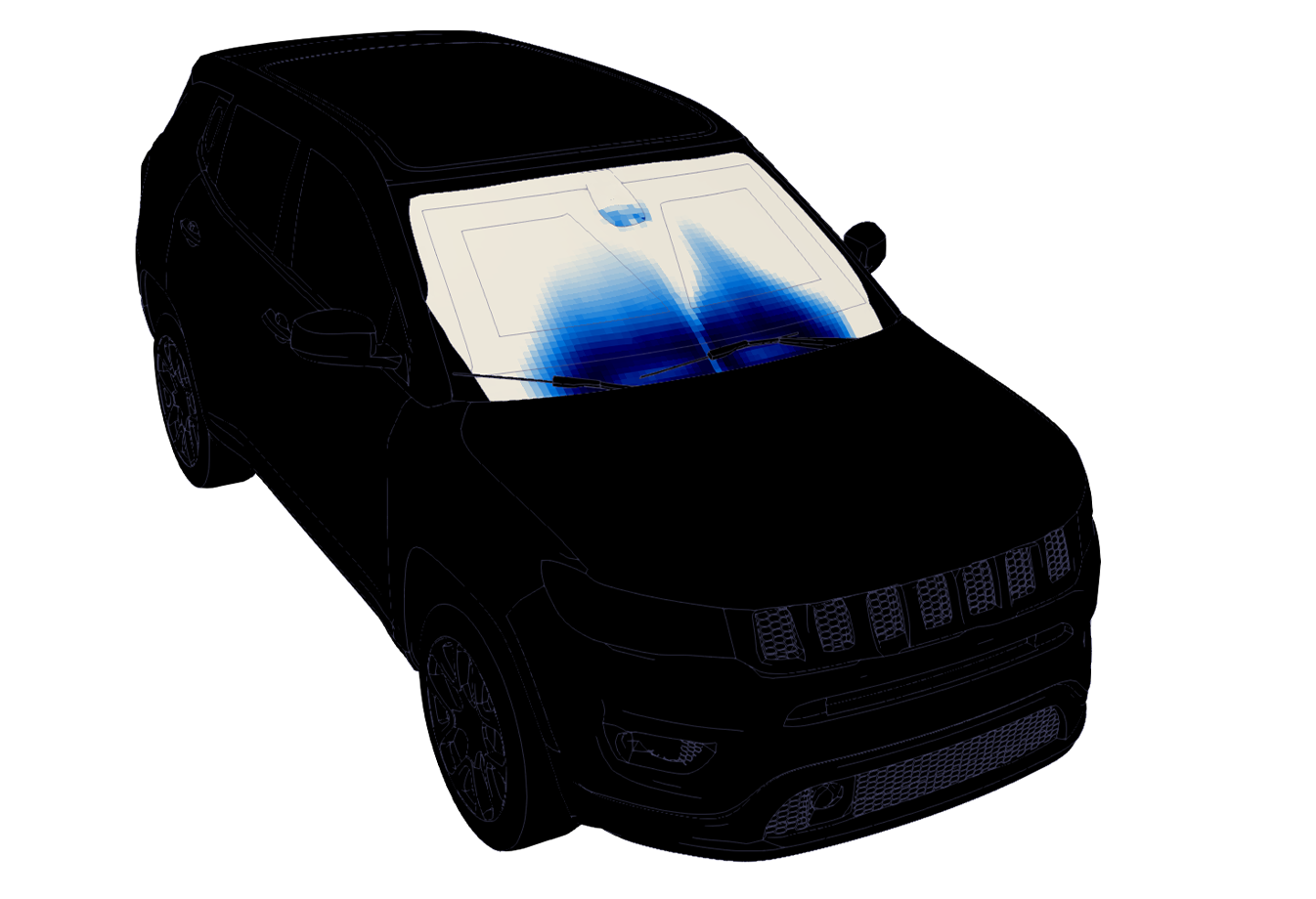

Continue ReadingOptimizing Windshield Defrost Performance Through Thermal Simulation

By

Deniz Hinz on April 24, 2025

Ensuring clear windshield and side window visibility in cold weather is a critical aspect of the vehicle development process. Traditional wind tunnel...

Continue ReadingThermoAnalytics 2025.1: Powering Multi-Physics Innovation

By

Steven Patterson on April 17, 2025

The latest release of ThermoAnalytics 2025.1, includes powerful enhancements across our suite of thermal simulation tools: TAITherm, MuSES, and...

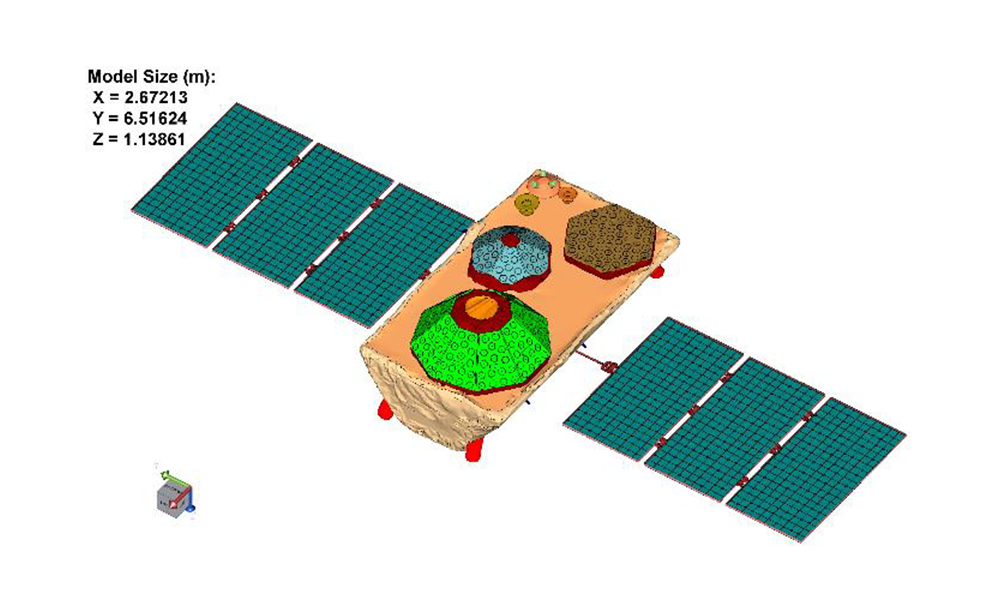

Continue ReadingSatellite Durability: A Coupled Thermal-Electrical Simulation Approach for Optimization

By

Corey Packard on March 19, 2025

The burgeoning field of low Earth orbit (LEO) satellites presents unique challenges forensuring long-term mission success. Small satellites, often...

Continue Reading

Submit a Comment