It's a hot August day. You're in the car on the way to a wedding. You have the air conditioning blasting. But as the sun beats down through the windshield, sweat collects on your spine as you lean into the seat.

I bet you've been in a similar situation. Even though the air temperature is relatively cool, you still feel uncomfortable. Why?

Because comfort is determined by more factors than just air temperature.

Get a true prediction of comfort

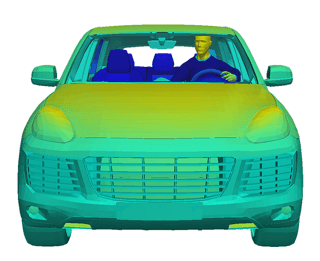

HVAC systems are the primary way OEM's bring comfort to the cabin environment. These systems create airflow, cooling or heating the cabin to the desired temperature. But as user-experience becomes king, designing for comfort is the only way to create an HVAC system that is dialed to perform.

For comfort, temperature is the main driver. But to get a true prediction of what a person is feeling, you must consider the entire context of the environment including:

- heat transfer through contact (i.e. sitting on a seat)

- environmental factors (i.e. solar loading)

- preconditioning (What was the person doing before they got in the car? What are they wearing?)

- and understanding the HVAC system in conjunction with other systems (i.e. heated or ventilated seats or recent integration of radiant panels)

Modeling heat transfer, as well as human thermal sensation & comfort, will allow you to see if your design provides real comfort.

Integrate HVAC with other systems

Another challenge engineers face is integrating HVAC with other systems. Vehicle interiors are tightly packed. With infotainment and other controls vying for space, HVAC engineers often must work around the geometrical restrictions of other components.

But by utilizing thermal sensation & comfort simulation, you can work with other teams early on to consider vent placement, size of components, and other design decisions all while visualizing the impact changes will have on the end user.

How do you go about simulating all these elements?

.jpg?width=543&name=alejandro-salinas-189861%20(2).jpg)

Use the right tool for each phase

Generally speaking, the best option is to do a coupled simulation. Thermal (heat transfer simulation) and CFD (flow simulation) together will show you the complete comfort strategy. Coupling the two codes together also gives you faster run times necessary for design decisions than just CFD alone.

Of course, where you are in the design phase matters. If you're nearing the end of a design, where accuracy is paramount, a highly-detailed CFD model may be exactly what you need. But for early- to mid-phase simulation, a coupled scenario features the data and speed that is key for those phases where a certain level of inaccuracy is tolerable.

Be realistic about what you need at each phase of the design. Don't waste time or resources. Don't use the slow, heavy sledgehammer of CFD when you really need a faster, simpler answer from a coupled simulation. Use the right tool for each phase.

Create a process for innovation

It's no secret the industry is honing in on user-centered design. The sooner it becomes your focus, the better your designs will be tailored to your customer's needs. Simulation creates an opportunity to focus on the human interaction (using a top-notch thermoregulatory model), to get a true prediction of comfort, and use the right tool for the job.

In order to create innovative products for your customers, you must use a process that allows for innovation.

If parts of your HVAC design process need an upgrade, drop us a line. We would love to help you find the right tool that streamlines your process.