You’ve likely been reading a lot about failures in lithium-ion batteries in recent years: cell phones spontaneously combusting, major aircraft battery fires, electric car batteries catching on fire.

Advances in battery technology bring both promise and peril, it would seem. But the good news is this: advancing right along with them are innovations in technology and processes used to test, predict and mitigate these failures before they ever get to the mass market.

Thermal Runaway on the Runway (and Elsewhere)

Whether it’s occurring in phones, planes or electric automobiles — or anywhere a battery is housed — the cause is typically a phenomenon known as “thermal runaway.” This occurs when certain chemical reactions in the battery start to create a self-propagating chain of events, with each one building on a thermal condition generated prior, that eventually escalates out of control. This can happen in a matter of seconds and can result in a fire or what some observe to be an “explosion.”

You’ll note that certain commercial products containing such batteries warn the user against overcharging the battery, or discharging it too fast. These are certainly among the preventative measures, but obviously not the best risk management techniques, as the product is presumably already in the hands of a novice user at that point.

Manufacturers, then, need to employ product designs that either shield these batteries from potentially dangerous thermal runaways, or do sophisticated testing and analysis to make sure these runaways won’t occur. Or both.

Simulating the Real World in the Virtual Lab

Given the speed of innovation in the battery industry, designers and manufacturers are at greater risk than ever before of going to market with a potentially faulty design. This, of course, increases warranty costs, opens the door to expensive litigation, and generally adds to costs for testing and producing safe products.

These manufacturers have options: Best-guessing based on informed experience, inflating margins to cover the additional anticipated costs, or expensive and time-intensive laboratory testing, which by its very nature will destroy your test specimen if it fails.

Or a newer option: Simulation.

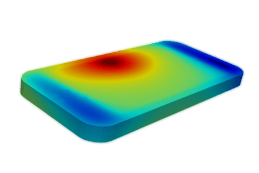

Sophisticated software can now virtually test a battery’s performance in its product environment, without the need to actually build (and possibly destroy) physical prototypes. Importantly, this simulation allows the tester to perform such analysis in its real-world, transient environment, so that one can better predict how the product and battery will be exposed to actual thermal loading conditions during use...not just in a steady state. (See the most common mistake engineers make when thermal modeling.)

Such software can simulate potential failure scenarios to anticipate the boundary conditions that will cause a thermal runaway scenario. One is also able to establish bounds on various conditions in order to ascertain which thermal limits might exist during charging or discharging, say. Once these boundaries are established, the simulated model can determine when, where and how these conditions will be exceeded. Once they are exceeded, will a runaway be triggered? And, if so, how does the manufacturer redesign the product, component or battery housing to arrest it?

Other simulation scenarios might test how the battery holds up to prolonged use, how it performs in extremely hot environments (sitting under the sun) or warming up after extended exposure to cold (sitting in a cold car). In the real world, the scenarios are seemingly endless. And so it is in the simulated realm.

Bottom Line: It’s Better for the Bottom Line

Design teams can now simulate the chemical reactions that lead to thermal runaway in a safer, more reliable, more cost-effective away than ever before. Whether a manufacturer is trying to save money, save itself from litigation, save face or potentially even save lives, the most effective and realistic simulation of real-life battery performance is the most logical place to start. It’s an investment that pays, not costs!

That it can now be done in the virtual realm is game-changing.

To learn more about the capabilities and practical applications of the Battery Extension, visit our website.