There was a time when having air conditioning in your car was a luxury feature. Now, technology has progressed and air conditioning and other HVAC controls come standard in baseline models. As customers, our expectations for creature comforts have increased as the technology has become readily available.

Accommodating lifestyle shifts and improvements to comfort are not the only priorities for engineers and OEM's at large. They are also looking to manufacture vehicles that are more fuel and energy efficient. Balancing comfort and efficiency can be a tight rope to walk.

-252042-edited.jpg?width=600&name=patrick-tomasso-110970%20(2)-252042-edited.jpg)

Thankfully, new strategies in thermal comfort are helping to make that balance a little more manageable.

What is Localized Comfort?

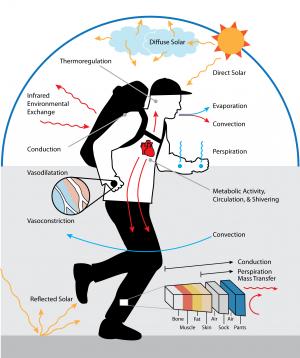

One strategy is to use localized thermal comfort. Localized comfort uses devices, such as heated steering wheels or active seats (seats that are heated or ventilated), to impact the thermal comfort of certain segments of the human body such as hands, neck, seat, etc. These devices in conjunction with HVAC systems can be used to create personal- or micro-climates.

So why use localized thermal comfort to create micro-climates for vehicle occupants? Here are four reasons.

1. Increased Fuel and Energy Efficiency

It takes a considerable amount of energy to heat or cool an entire cabin environment. Comfort achieved through a localized thermal comfort strategy takes less energy since it uses a targeted approach to bring some of the more critical body segments to comfort. With less energy diverted to heating or cooling the cabin, more energy can be used to increase the range of an electric or hybrid-electric vehicle or create more fuel efficiency for a traditional combustion engine.

On average, 38% of all trips were personal vehicles with a single occupant[1]. This makes it more efficient to condition only the parts of the vehicle needed for comfort.

2. Faster Time to Comfort

Along with conditioning the cabin efficiently, comes the ability to do it more quickly. Bringing a steering wheel, seat, or radiant panels up to temperature can happen more quickly than getting the whole cabin to achieve the desired temperature. This means the occupant will feel comfortable more quickly – (or let's face it) they will be uncomfortable for a shorter amount of time.

3. More Design Options

Using a localized comfort strategy can open up new design options for the interior of the cabin. New dashboard configurations can be worked, different placements of vents and more convenient location of controls and media can be tried if the occupant's comfort is not solely dictated by the location of the vents. Different design configurations can open up new ways to delight buyers.

4. Localized Comfort can be Simulated

Localized comfort does have its hang-ups. It is easier to design controls for a simple HVAC system that is only looking at one factor, the cabin temperature, than a system that includes multiple localized comfort devices AND an HVAC system.

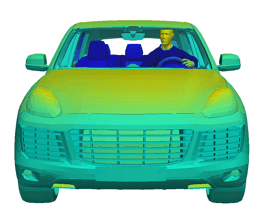

However, if companies want to achieve better results for thermal comfort and efficiency a localized strategy makes a strong case. The good news is that it can be simulated using advanced CAE programs.

These programs will allow your team to not only test their specific subsystem concepts but to work with other teams to see how the whole comfort strategy works comprehensively. Using simulation can also help you:

- understand how comfortable the cabin would feel under all kinds of environmental conditions

- understand how comfortable (or uncomfortable) an occupant would be in the cabin under chosen environmental conditions

- and also allow you to pre-condition your scenario (i.e. a man wearing a business suit runs to his car on a hot day and gets in, what's his time to comfort using your current design?)

To do this type of simulation right, you’ll need an advanced thermal simulation program. One that produces results quickly enough for design revisions but accurately enough that you’re confident making those decisions. To model human comfort, you’ll need a thermal simulation software that includes an advanced physiology model. If part of your process includes modeling airflow, coupling with a CFD program will allow you to visualize both while still keeping your run time brief.

Simulation Will Save You

While this type of shift can cost you in many ways, it's also going to save you in many ways. Not only are you and your team going to be prepared with a new strategy that will allow you to get down to the important stuff (like innovation) but one that will save you on costly prototypes, wind tunnel time, labor, and travel. Think about it. You can see thermal results for all your design iterations, climates, and comfort metrics through an advanced simulation tool before spending money building a prototype. Pair down your design choices to the best designs before shipping your costly prototypes and your talented engineers to extreme and far off locations to be tested.

While looking to innovate on what type of design you use to create a great vehicle, you should also question the method which you use to build that vehicle. Is your current method efficient? Does it allow you to get the data you need? Can you use a different method that helps limit assumptions?

If you're looking to integrate or improve an existing localized thermal comfort strategy, find out if a simulation method is right for your design process.

______________________________________________________

[1] Bureau of Transportation Services. "Daily Passenger Travel." Daily Passenger Travel | Bureau of Transportation Statistics. N.p., n.d. Web. 27 July 2017.