When integrating new technology into your design, you're rarely faced with a singular issue. Instead, you juggle multiple challenges, restrictions, and dependencies when redesigning your product.

Integrating active seats, or seats that are heated, cooled, or ventilated, into the design of a car is one such problem. OEM's look to advance active seat design not only to increase passenger comfort but also to reach that level of comfort in the most efficient way possible.

Today, cars are becoming more efficient so there is less waste heat available for conditioning the cabin air. The challenge then, especially for those designing HEV's, is where to get the energy to heat the interior. Understanding how much energy you are drawing from the battery or system is crucial in understanding the overall effect on the design. For example, in an HEV, if the energy drawn from the battery to heat the seats is significant, the distance the car is able to drive on battery power will be lessened.

So, what is the best way to account for all these questions when designing active seats or the cabin around them?

A traditional approach to integrating active seats into an overall design would involve making educated assumptions about how the seat will interface with the occupant as well as how much energy it will draw and how it will interact with the surrounding cabin and HVAC system. These assumptions are then used to create a prototype which is then validated by testing, fixing, and repeating. This approach will eventually produce an acceptable design but at what cost? Both time and money are valuable resources, and this method is not conservative of either.

Simulation Offers a Predictive Solution

Engineers are seeking a more predictive solution. The test-and-fix paradigm does not lend itself easily to design changes or innovation, especially in complex interconnected systems. Simulation allows engineers to virtually test designs. But what type of simulation method is advanced enough to offer real predictive accuracy and validation?

The beauty of simulation is that it is helpful during the whole process. You can scale back on the detail of a simulation for an earlier step in the design phase and still receive accurate results.

Know the Effect Your Design Changes Have Right Away

You can create a detailed model if you have the geometry and the properties of the seat. By simulating the materials and mapping the way the seat is heated, cooled, or ventilated – you can test different materials, the impact of changing the wire paths in the seat, and the amount of energy used to heat the seats – all virtually! This type of flexibility early in the design phase is an opportunity for innovation and allows you to eliminate design choices that aren't going to work for you.

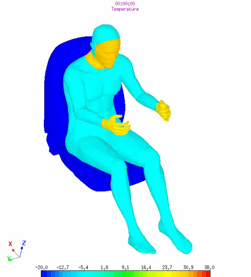

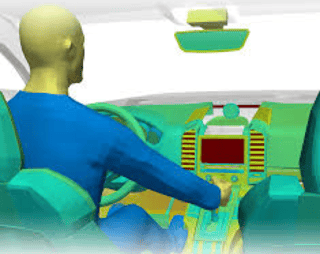

Running your design through simulation will also give you an opportunity to see how your seat design will integrate with the HVAC system to create a comfortable cabin environment. First, the simulation would allow you to find out what combinations of temperatures would make the ideal environment. The simulation will help you predict how much heat will need to be added to the seat or the air to achieve those temperatures. Through simulation you can find the balance between adding heat to the seat or to the air to achieve comfort while reducing the overall energy consumption. The results of these 3D thermal comfort simulations can then be combined with 1D systems simulations to predict how much total load will be required from the vehicles power plant and how that will impact fuel economy or range.

Working with ventilated seats is similar. If a fan or cooling mechanism is added to the seat, how much warmer should the surrounding air be allowed to get while maintaining thermal comfort? You can answer this question by simulating all these effects on a virtual human including the sensible and latent heat transfer. You can also simulate the heat transfer to the cabin air from the surrounding environment (like solar load from the sun) and predict the amount of cooling that is required. Then, systems models can be used to predict the total load that this amount of air conditioning, seat ventilation, and seat cooling would put on the vehicle power system (including inefficiencies in the refrigeration loop, etc.)

Simulations Can Be Validated Objectively Using Manikins

These simulations can then be validated using physical manikins. The STAN manikin was developed specifically for working with seats. It can be used to measure effective seat properties such as thermal resistance and capacitance and it can measure additional heat transfer provided by seat heating, cooling, or ventilation. The STAN manikin is weighted to compress a seat the same way as a seated human and thus will measure the seat properties in its compressed state. The manikin measurements can then be compared with simulation results to verify modeling assumptions about the seat construction and compressed material properties.

Our Process

For our simulation purposes, we utilized TAITherm and the Human Thermal Module. TAITherm allows us to model a detailed seat, complete with material properties, and understand energy draw. With the Human Thermal Module, you can accurately model the human thermo-physiological response to its surroundings. The Human Thermal Module also predicts comfort metrics based on the environment and physiological conditions. For our 1D calculations we utilized the GT-SUITE code and the manikins we have used in our workflow are a product of Thermetrics.

In our next blog about seats, we will take a look deeper into how a simulation methodology can help you integrate your seat design with the entire cabin and simulated human.

If you want to know more about how understanding energy draw using a simulation methodology could improve your design process, please don't hesitate to reach out to us.