As we continue to examine optimization techniques to front load design decisions to achieve competitive advantage, we take a deeper dive into how innovative manufacturers are becoming increasingly adept at eliminating cost, materials, time and waste from design and manufacturing processes.

One point bears emphasis: The concept of “front loading” should not be considered something that only happens at the very early stages of the design process. In fact, the companies that are employing simulation processes and technology throughout the complete lifecycle of design, production and post-production are the ones that are maximizing their optimization ROI.

Optimization at Every Step of the Process

In simple terms, the standard lifecycle for product development consists of four primary phases:

- Design

- Pre-Development

- Development

- Post-Development

Critical decisions are being made at every phase of development. The quicker and more accurately decisions are made, the greater the savings on time, materials and cost. Those decisions fall into three “buckets”:

- Geometric (the shape and dimensions of components and systems);

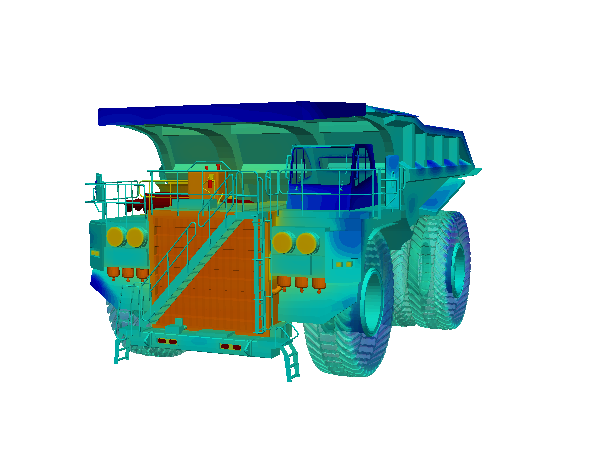

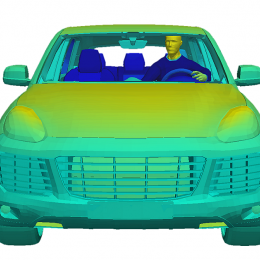

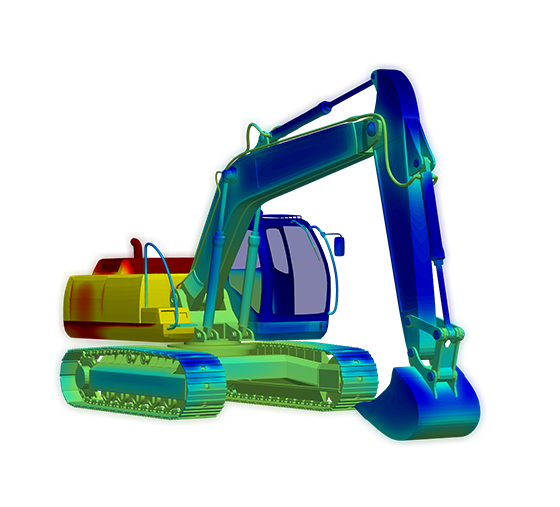

- Thermal (how is energy/heat being used, dispersed and absorbed);

- And from the standpoint of Boundary Conditions (the varying circumstances a system will be exposed to, be they weather/climate, transient driving conditions versus steady state, etc.)

Optimization looks at all of these aspects to find one solution that addresses them all, and this can be done throughout all of the phases above (along with the sub-phases that each may include).

The challenge comes when you have different teams (for example, engineering and design, or OEM and supplier) all asking different questions to achieve different outcomes related to optimization. The only possible way to satisfy all stakeholders quickly, accurately and efficiently is through the application of sophisticated simulation tools — tools that go far beyond what any single CFD or CAD solution can possibly achieve.

There is an explicit and tangible monetary value to finding not only the best possible solution to each of these challenges, but also the most profitable solution.

Maximizing Profit While Minimizing Design-to-Development Lifecycle

What the world’s most advanced automotive manufacturers have learned is that optimization via simulation is really a double optimization. By eliminating unnecessary testing time, materials and other attendant costs, simulation allows all of those disparate teams to account for variables, simulate conditions, and arrive at optimized decisions in ways that far outpace their competitors. In some cases, OEMs have managed to trim a seven-year design-to-marketing lifecycle to four or five years. Scenarios that previously took days or weeks to test have been simulated and verified in a matter of hours.

Design: In the early stages of conceptual design, you know very little in the way of specifics, in terms of design, boundary conditions, etc. As a designer or engineer, you may not even know yet what vehicle you’re ultimately working on. Yet, these design and engineering teams are being expected to optimize their decisions. The only way to do that is with simulation. Rather than hypothesizing, prototyping and testing, you can change solution parameters — materials, geometric properties, contour angles, and so on — without limitation (as you would in the manufacturing phase). You can explore possibilities in this phase because you can vary these parameters to get as many samples as possible, if you use simulation as your optimization technique.

Pre-Development: In the next stage — pre-development — there are new challenges: constraints on packaging, materials, contours, etc., as the vehicle and components have now entered the manufacturing process. Now the engineer has to assume the concept from a design team and convert it into “pre-reality.”

Using simulation software, engineers can create testing scenarios and expose a virtual model to those scenarios to see how they will respond to various sets of conditions. In the process, you mature the design much more quickly because you are not burdened by the time and expense of physical prototyping. Again, the double optimization of time and cost comes into play, which moves the project on to the development phase more quickly and at far lower cost.

Development: Now we are building a car or truck, and each independently designed system is integrated with all of the other systems in the vehicle. How do they interact? Perhaps we’ve discovered that a given component needs to move in order to satisfy the integration of another…how does that move affect another nearby component or system? What if the car is driven in Dubai? Or northern Canada? In this phase, the constraints that present are the conflicting teams’ goals and ends, as somewhat of a power struggle emerges as to what is compromised and who does the compromising.

Because not one single team can reliably answer all of these questions, they all do independent testing. And some of them might test using steady-state assumptions, when they should be testing under transient, real-world conditions. This takes time, costs money, and can sometimes result in conflicting testing results.

But more and more are realizing that this is a critical juncture for optimization via simulation, as you avoid all of these tests altogether. In effect, you only do the testing once the car is being assembled and all variables have been simulated and proven out. Optimization during the development phase leads to profitability because you can make design changes quickly and cost-effectively — virtually — and you only have to incur the time and costs of testing once…more so to verify what simulation has already modeled, as opposed to a costly and continuing cycle of test-and-fix-, test-and-fix, test-and-fix.

Post-Development: This stage might otherwise be called the “Compliance Phase.” Now that the vehicle has been developed, the manufacturer has to account for a whole new set of variables related to where the vehicles will actually be sold and driven. Each country (and even each state, province or territory within each country) has its own unique government regulations on safety, fuel efficiency and emissions, among other compliance obligations. In other words, that which has already been optimized when the vehicle was being designed and developed now needs to be optimized for each country and locality in which it will exist in the market.

These design and engineering teams are now once again being asked to account for changing geometry, performance, thermal management, etc. But if you’ve optimized via simulation at every step along the way, you shouldn’t have to test these vehicles again, or take them to the various countries to see how they comply. This can all be accurately and reliably simulated.

In other words, if you’re paying to fly prototypes or finished models all over the world to see if they comply with governmental or climate realities as they exist on the ground, you’re leaving money, time and innovation on the table, while at least a handful of your competitors are beating you to the proverbial punch…and enjoying all of the obvious ROI and competitive advantage that comes along with it.

The Time to Optimize is Now! (…And Later!)

The reality is that, as a new model or redesign progresses along the pre- and post-development lifecycle, it gets more and more complex to account for scenarios that range from geometry to thermodynamics and from performance to governmental regulation. As you and your team move further along, there are more moving parts (literally and figuratively) and the required level of detail gets greater and greater. As a result, while the stakes get higher, the opportunity to optimize gets greater…but so does the risk of not optimizing.

The sooner you integrate simulation into the process, the greater your returns will be in terms of profitability, innovation and market share. But the longer you stay with optimization, the more you get out of it.

Learn how the TAITherm system is being applied to optimize design, engineering and production processes tools to inject efficiency and profitability into the development lifecycle.