We’ve examined at great length the inherent advantages of using simulation software to “front load” design decisions as a competitive advantage for automotive and other manufactures looking to eliminate cost, materials, time and waste from the design process. But how can designers and component owners optimize the process flow to make ROI-producing decisions quicker and more accurately, even when operating in somewhat isolated silos from one another?

Suppose a particular vehicle is extremely early in the design cycle — perhaps at the conceptual phase. Designers and component owners may be concurrently — but separately! — working to solve thermal management and other design/production issues…each asking similar questions of a given proposed tweak, but to different ends. To make things more challenging there may not even exist a complete vehicle model or physical prototype, so different teams are working separately to address issues, using different sets of assumptions corresponding to their independent issues.

To say the least, this scenario is less than optimal.

Simulation to the Rescue

Suppose each team (design and component owner) is presented with a new design scenario. An engineer is thinking of moving a particular cable six inches to the right or left due to packaging constraints. The designer may be chiefly concerned with the aesthetic implications of what this change means; while the component owner (or subsystem leader) may be more concerned with the thermal management implications of moving that cable closer to a heat source.

The component owner may need to know the temperature exposure and its duration above a particular thermal threshold, predicted reliably enough to move forward on the change order. The design team is already hard at work making the change order aesthetically pleasing and possible. Yet both are handcuffed until they get the thermal management answers they need.

Without a complete vehicle model, without a physical prototype, without (perhaps) even any knowledge as to what end vehicle product line is, two individuals or teams may now be forced to wait 4-8 weeks for an answer to a question about a hypothetical change.

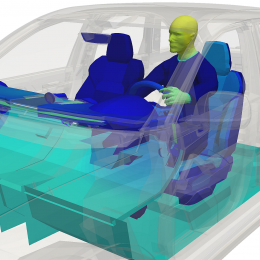

Imagine having those answers in 4-6 hours — not weeks. Imagine not having to build a complete vehicle model or physical prototype to get the answers. And imagine that no costly and time-intensive testing is needed. This is where simulation comes in, to replicate the hypothetical scenario in the virtual world using a simple sub-model of the problem area, and to understand with accuracy and precision all of the potential thermal management outcomes of the requested change.

What would that time and cost savings do to your ROI?

Real-World Example of Real-World Simulation

Simulation is far from hypothetical, however. Real-world manufacturers are using simulation in real-time to understand, identify and solve issues earlier in the design process. This comes at far lower investments in time and engineering costs, dramatically injecting efficiency into their decision-making process.

One premium sports car manufacturer was recently considering a redesign to the rear end of a vehicle that featured a large rear mounted V12 engine. With a muffler and four exhaust pipes extending out from the rear bumper, the manufacturer was experiencing some challenges related to potential burning or melting of a prototype’s rear bumper.

The questions were raised: “What if we extended the exhaust pipes 20 centimeters out from behind the bumper? What if we moved them a few centimeters this way or that? Would that remediate the problem?”

The engineers’ chief concern, of course, was the function of the exhaust system. The designers were mainly concerned with the new look of the rear of the vehicle. The component owner needed to be ensured of safety and performance of the whole system. And, to the OEM, all of this was critical.

Keep in mind, none of these teams even had a complete vehicle model — they weren’t even told what vehicle type they were working on, as it was still in the conceptual stage. This was a perfect test case for the concept of using front loading simulation.

Using the TAITherm simulation technology, the result was turned around in under an hour for each possible configuration — bringing the pipes in…moving them up…moving them down…extending them out from the bumper. No prototype, no physical testing. No time wasted; no money wasted. Simulation allowed all of the disparate project teams to understand and reliably predict the implications of every possible design/engineering scenario on a system level basis.

Best of all, TAITherm allowed this simulation to be conducted as a transient - condition — not steady-state — to account for fluctuations in boundary conditions and real customer driving behaviors. Using sophisticated software such as this allows design and engineering teams to not only discover potential thermal management issues, but to specifically identify the component, location, severity and nature of the problem in all scenarios during real world conditions.

Best of all, TAITherm allowed this simulation to be conducted as a transient - condition — not steady-state — to account for fluctuations in boundary conditions and real customer driving behaviors. Using sophisticated software such as this allows design and engineering teams to not only discover potential thermal management issues, but to specifically identify the component, location, severity and nature of the problem in all scenarios during real world conditions.

How Simulation Can Optimize the Decision-Making Process

In our next article, we will examine and detail how manufacturers, designers, engineers and component owners can optimize the decision-making process by front loading the design phase with better, more robust, more reliable and more predictive information than ever before. We will explore when, why and how to optimize the decision-making process using simulation.

All of this will reveal, if it hasn’t already, the tangible and dramatic ROI such technology and processes can inject into your system that can be reinvested into the company and help you gain competitive advantage in an increasingly competitive world.

Learn more about the TAITherm system’s tools to help visualize and front load thermal management.