The concept of “front loading” is not entirely new to automotive manufacturers, who are becoming increasingly adept at eliminating cost, materials, time and waste from the design process. The industry is at the early-adoption stage of manufacturers (in automotive and other sectors) embracing new, robust simulation tools to front load design iterations, providing even greater return on investment than ever before.

“Front loading” in the general sense is defined as “distributing or allocating assets unevenly, with a greater proportion at the beginning of an enterprise or process.” The benefits are fairly intuitive: The sooner you can identify issues and opportunities in the production lifecycle, the more efficiently and effectively they can be managed.

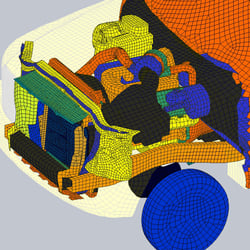

Simulation technology takes front loading to a higher level, allowing manufacturers to make quicker, more informed and more powerful decisions very early in the design or conceptual phases of production. This allows the design and engineering teams to arrive at more effective engineering solutions early on — even before any design or prototyping is done.

Simulation technology takes front loading to a higher level, allowing manufacturers to make quicker, more informed and more powerful decisions very early in the design or conceptual phases of production. This allows the design and engineering teams to arrive at more effective engineering solutions early on — even before any design or prototyping is done.

Simulate and Innovate, Rather than “Test and Fix”

The all-too-common “test and fix” methodology can often have designers, engineers and manufacturers chasing misidentified issues down an unknown number of “rabbit holes” that lead them to the wrong conclusions, only to send them back to the literal drawing board time and time again. Prototypes are essentially built by the human hand and parts are ordered in very limited quantities (both of which coming at great expense). They test prototypes in the physical world (incurring further costs), then do it over and over again until a component can safely and reliably graduate to the next phase. As a result, manufacturers amass very real costs and lose valuable time (time that could have been spent on further development).

Front loading using simulation eliminates as much as 80% of that unneeded cost, time and (often wasted) materials. The advantages to using simulation tools to front load design decisions are many:

- Time – Simulation tools allow design and engineering teams to accurately and reliably “read and react” quicker than ever before. For example, front loading allows engineers to study heat shield changes in a vehicle before prototypes have been built. This allows for fast trade studies when considering changing thickness, materials, or layering of a heat shield.

- Cost – With simulation, there may not be a prototype needed in the design phase. Rather, by virtual prototyping, it is possible to design and test something without building it.

- Flexibility - Simulation teams often receive component temperature requests. Perhaps there is a new material under consideration, or the design team would like to route a cable closer to a heat source. Running simulations before testing offers the design team flexibility to explore more options and ultimately resulting in better designs and less failures.

- Revenue – By cutting material, labor and testing costs, front loading simulation contributes directly and significantly to the bottom line. And these front-loaded decisions ultimately lead to fewer design flaws and future liabilities, further tipping the ROI in the manufacturer’s advantage.

- Competitive advantage – Heavy vehicle and truck manufacturers may not have been as quick to adopt front loading as some automotive manufacturers. But imagine the competitive advantage one vehicle maker using simulation tools to front load engineering solutions has over one that is not. Because vehicles are expensive to build by their very nature, manufacturers have been slower to innovate, meaning those that do will be pulling away from the competitive field in significant measure.

These are just some of the very clear advantages that can come from “front loading” your simulation process. We will continue this discussion with a second blog, which will further examine how early in the process simulation might make sense.