When discussing the global automotive market, you can't get away from the topics of fuel economy and emissions. To be compliant with tightening standards (such as Corporate Average Fuel Economy (CAFE)), OEMs are buckling down on their approaches to greater efficiency.

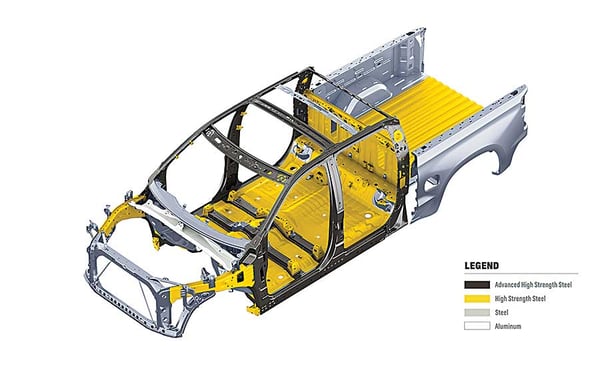

While we can expect a greater number of HEVS and EVs to hit the market in the coming years, automotive manufacturers are focusing significant efforts on their lightweighting initiatives. Lightweighting has emerged as an effective method for meeting fuel economy and emissions standards because it is straightforward. In simple terms, lightweighting is replacing existing parts with lighter components that serve the same purpose.

In our previous blog, we looked at how simulation allows engineers to explore different lightweighting options and gain confidence in their chosen design before making investments into prototyping. Simulation software is essential to pre-prototype design investigation. To make strides in optimization using physical prototypes is costly and time-consuming. Cost and difficult deadlines make narrowing down your design options using prototypes unfeasible with the demands of the automotive industry.

Why You Need Thermal Simulation for Lightweighting

Thermal simulation is a key ingredient to a successful lightweighting strategy. Since lightweighting involves using advanced materials (aluminum, plastics, composites, etc.) in exchange for heavier traditional components, it is crucial to know if these new materials will be able to withstand the thermal conditions they will experience.

Using thermal simulation software, you can run a trade-off study to determine which material(s) will meet thermal management requirements while achieving lightweighting targets. Running a trade-off study using TAITherm is simple because it allows you to:

• manage your materials

• choose your meshing method

• include all modes of heat transfer

• and know what components are succeeding or failing and why

Manage Your Materials

TAITherm makes it easy to manage a database of material properties (including standard materials and custom properties from suppliers), assign the properties to the relevant components in your model, and visualize where materials are used. Material property values may be constant or temperature-dependent to capture varying material behavior over a wide temperature range. In TAITherm, Material Properties are used to define the density, specific heat, and thermal conductivity; Surface Conditions are used to define the thermal emissivity and solar absorptivity for radiation heat transfer. After you establish the properties, you can color the geometry by Material or Surface Condition to verify the setup or help a colleague visualize where new materials have been applied.

Choose Your Meshing Method

TAITherm allows you to create both low-fidelity, fast-running models and high-fidelity, high-accuracy models depending on your requirements and resources. One of the critical ways to effect this trade-off is to choose a thin shell or volume solid mesh. With a thin shell, the thickness (for one or multiple layers) is defined parametrically. With volume solid mesh, the thickness of the part is determined by the solid geometry and can vary locally. Conduction paths for some geometry may also be easier to represent using volume solid mesh. The advantages of volume solid mesh come at the cost of additional pre-processing and analysis time.

You can also mix and match meshing methods depending on your needs. For example, you can use a volume solid mesh for only the most critical parts and their immediate neighbors. It can also be advantageous to run a fast shell model to get an initial answer but later refine the model using volume solid mesh to ensure the accuracy of your results.

Utilize All Modes of Heat Transfer

To get an accurate picture of how the redesigned component will fare, you will want to ensure your simulation includes radiation, convection, and conduction as they would occur in that scenario. Simulating only one or two of the modes instead of all thermal effects will yield an incomplete picture. Modeling all modes of heat transfer can be crucial in lightweighting analysis since changes to materials can often result in complex and unexpected changes. For example, a higher conductivity material can result in increased lateral conduction, which might, in turn, cause increased radiation heat transfer from areas of the component further away from the primary heat source.

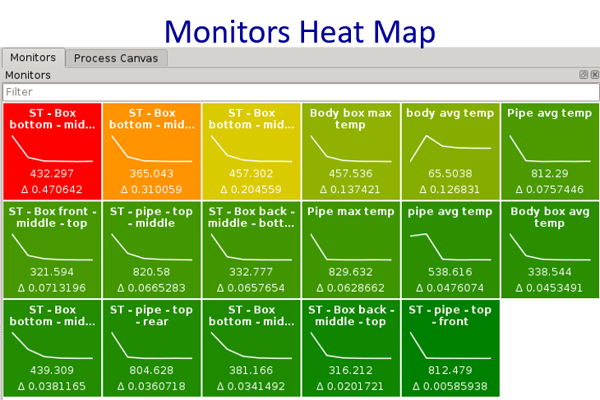

Know What Components are Succeeding or Failing and Why

Once you can see how your design operates under realistic thermal conditions, you may have areas or components that need troubleshooting. Using TAITherm's post-processor, you can quickly determine which parts are failing or are close to failing. Using the Relations Tab, you can understand why those components are not succeeding. The Relations Tab provides a list of contributors based on radiation, view factors, or conduction influences to and from the selected parts. Understanding the contributors might shed light on additional design changes needed to use the lighter materials and still meet thermal requirements. Thermal Reports can also be used to quickly generate the same data exports and images from multiple models using the same settings, so A-B comparisons are easy to document. These post-processing features can aid you in your primary objective—to select lighter materials and ensure they are thermally managed.

Better Predictions of Service and Safety

In many cases, you may have new materials that cannot exceed a specific temperature. That is easy enough to determine using a steady-state scenario. However, to optimize a design, engineers may also want to know that a particular component will be able to withstand a specific temperature for a certain amount of time. For example, a sensitive component made from a composite material may not exceed 150 degrees Fahrenheit at any time. But, would that part still be successful if it was at 130 degrees Fahrenheit for a few hours?

Only a transient simulation will allow you to answer realistic scenarios. You can then achieve more significant optimization instead of designing for the worst-case scenario. With TAITherm, you can simulate and test both single (continuous) temperature limits or short-term temperature limits during a scenario of interest.

Couple for Complete Lightweighting Analysis

Once your design is thermally accurate, you can couple your thermal results to other CAE tools to see the full impact of the lighter weight components. TAITherm easily integrates with FEA programs for thermal stress simulations, CFD for highly detailed convections analysis, or other CAE codes for durability studies.Coupling with other codes is easily achieved using CoTherm. With CoTherm, you can build upon existing templates for standard coupling processes or develop a custom process using resources, tasks, and python journals.

As a process building and coupling tool, CoTherm gives you unprecedented flexibility and a common language for your process to share with others on your team or across teams. In addition to coupling, CoTherm makes it easy to run sensitivity, DoE (design of experiments), or optimization studies to look at a range of uncertain parameters quickly.

You can take your design that's been successfully thermally simulated and easily carry those results into the next stages of your process.