In this blog, we will take a look at how to predict battery lifetime and performance.

Variables That Influence Battery Aging

The three primary variables influencing battery age are the state of charge, depth of discharge cycling, and temperature. State-of-charge is how charged or discharged the battery is. With simulation, you can design your battery for an optimal state of charge for a lifetime. Many automotive makers have discovered that between 20-80% is preferable for a lifetime for electric vehicles due to the complex nature of an EV battery’s life. Simulation can help you discover the best state-of-charge window for your product, as a high or very low charge can increase battery degradation.

Depth of discharge cycling is how often you charge or discharge the battery daily. The more frequently a battery is charged and discharged; its lifespan will be shorter. It’s generally not recommended to discharge a battery entirely, as that dramatically shortens the life of the battery. If you can reduce the depth of discharge, you may be able to initiate a thermal extension into the battery’s lifetime. Simulation can help engineers determine the appropriate depth of discharge and cycling for their products.

Elevated temperatures also cause batteries to age faster. While EV batteries perform better at high temperatures, they can become a safety concern for thermal runaways. It is essential to simulate the conditions the battery will have to undergo to get an accurate picture of safety and performance and to balance them with life goals.

Strategies to Decrease Battery Degradation

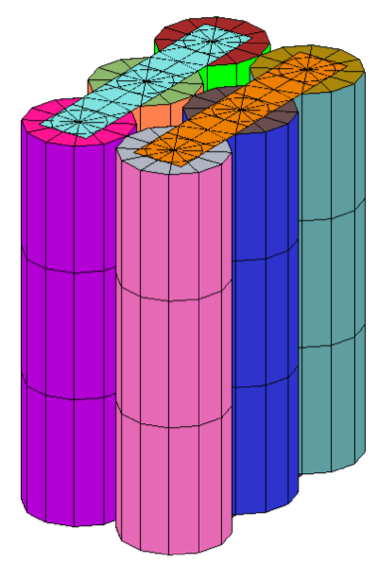

Engineers have sought out different strategies to decrease the rate at which EV batteries age. For lifetime analysis, there are two modeling approaches from which engineers can choose. One approach is a first-principles model that captures physics-driven effects. The second is an empirical model based on test data that characterize the thermal behavior of the degradation.

The first-principles model is one available approach for battery internal component design or if you have limited test data. This model allows you to modify basic elements such as component thickness or chemistry and observe how those changes can affect battery life. The empirical model is preferred for more detailed battery models since it is better calibrated to work with your test data. This is because the parameters that can be adjusted are related to the variables tested and not basic construction elements. The empirical is also better suited for working with complex analyses such as drive cycles or complicated usage scenarios. For the empirical model, ensure you run enough test scenarios and gather enough data to capture all of the variables you wish to analyze in your simulation.

Analyze More Variations Without Inherent Costs

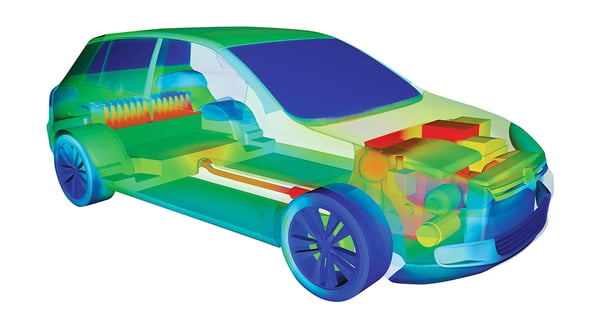

Thermal Simulation can help engineers understand how their designs will operate in the real world. Physical testing is timely and costly. It also does not allow an engineer to capture all applications or usage scenarios. Simulation helps manage tight budget restrictions by allowing designers to create variations without the cost of prototypes. Engineers can use these thermal simulations to iterate on model variations quickly to increase battery lifetime.

Assessing Battery Performance

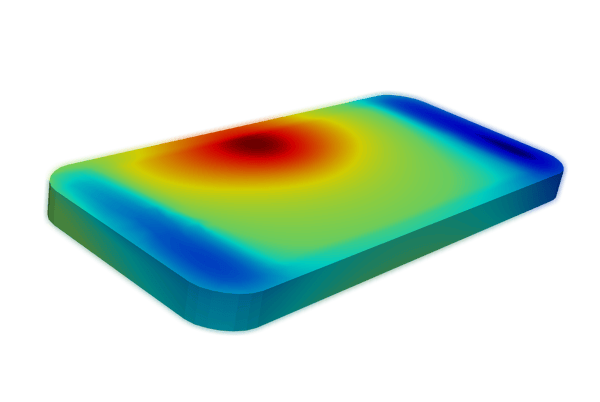

Complementary to battery life is performance. For battery performance, engineers assess usable capacity, power output, terminal voltage, and heat generation. Usable capacity is the amount of charge a battery provides, and power output is the amount of current the battery will produce. As the battery ages, it will produce more heat, measured as heat generation. These outputs are what help engineers determine the performance of their batteries.

To set up a simulation, engineers should characterize the battery using discharge testing and thermal behavior/characterization to measure temperatures during discharge.

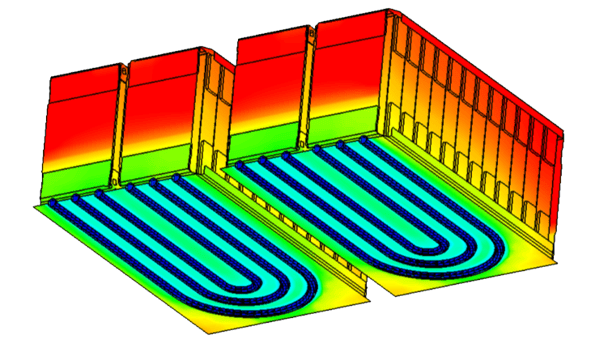

Batteries perform better at higher temperatures; they will age faster. Temperature is an aging limitation, not a performance limitation. However, EV batteries at too high a temperature can become unsafe and sometimes progress into thermal runaway. Engineers are working to minimize aging by controlling temperature within a range while keeping the battery in a performance range that meets customer expectations. Simulation can give engineers a detailed look at how their design can optimize age and performance. This balance can be managed by determining how elaborate of a cooling strategy they need to get the most out of their battery.

Characterize Complex Scenarios with Simulation

Without simulation, engineers would have to run the cycle repeatedly to determine how long it would take to age and how to juggle those priorities with performance. With physical testing, they can only test so many scenarios, and even then, it is not characteristic of what happens in a complex scenario such as an electric vehicle. If you want to predict how long something will perform, you need a test to run a broader range of conditions and simulate various environments.

Transient conditions are easily simulated using our TAITherm software. Backed with the Battery Extension, you can simulate a variety of use cases for a realistic evaluation of battery performance. Our Drive Cycle Extension can also use coupled 3D thermal and CFD models to provide realistic drive cycle data for your thermal analysis.

While it can be daunting at first to know what kind of simulations to run, our expert team of engineers can help you understand how to use simulation to improve your design process.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: