Design, prototype, test, repeat. The ultimate engineering process. Enter environmental simulation, a new method that is shaking the CAE world. Simulation has transformed the original iterative design process, exposing models to the environments they will perform in, prior to costly prototyping and testing. Preceding simulation methods, each design change made would force the project back to the engineering department for rework. This cumbersome process consumes valuable resources in a company, ultimately influencing the bottom line.

What Is Environmental Simulation?

Environmental simulation is the process of validating design in environmental conditions. It offers a feasible way to consider a much wider range of conditions than a product would be able to face in physical testing. This type of testing allows teams to change small parameters, repeat the simulation to quantify effects, and compare results between design variations. By leveraging this methodology, engineering teams are able to evaluate best and worst case scenarios very quickly.

Understanding the Need

Vehicle testing is one field that showcases the benefits of environmental simulation. The automotive market is a global market, selling to consumers in every climate around the world. The environments these vehicles face are intensely diverse, affecting them in many different ways. How can a company afford to run full lifecycle tests on each vehicle, in each environment, for the full cycle? On the other hand, how can a company afford not to? Imagine the consequences that would result from selling vehicles designed for users located in the hot temperatures of South America to consumers in the bone-chilling cold of the frigid Arctic. The heat shield properties implemented to keep vehicle cabins in warm climates cool would adversely affect those located in the Arctic, whose vehicle cabins and battery performance benefit from solar soak properties. Environmental simulation enables companies to ensure that the vehicles they ship to each location will perform at their full potential, maximizing user experience and customer satisfaction.

Accurate Inputs, Accurate Results

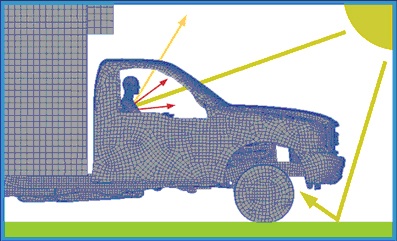

There are necessary inputs required for proper simulation including temperature, wind speed, relative humidity and cloud cover. It is also important to collect radiation data from the ground or items in the near vicinity, taking into account the effects of reflection and temperature on designs. The higher the accuracy of this input data, the higher the effectiveness of the simulation results. In the automotive industry, it is critical to acknowledge the surroundings the vehicle will perform in. For example, automobiles located in desert locations must be designed to withstand dust infiltration from potential sand storms. Environmental simulation can help teams understand the effects of wind and sand on these vehicles in the design phase.

Opposition to Simulation

Though companies routinely have difficulty launching products to market at a competitive pace, there is still opposition from those who are apprehensive to trust simulation data. This data is verified against physical test data that is collected through rigorous tests done on engineered designs in their natural environment. The process is reliable and efficient and enables companies to remain competitive as they forgo the time-consuming process of prototyping designs and physically testing in each market environment.

Process Improvement for Real Results

Environmental simulation enables CAE teams to streamline the engineering process, obtaining better simulation data at a quicker rate and optimizing projects early on. If your process is lagging and in need of increased efficiency, TAITherm, our cutting-edge simulation software is available for you. TAITherm helps avoid unnecessary production costs, design delays and inaccurate test results while shortening production cycles and providing a picture of real-world performance. If you’re interested in learning how our solution can make your process better, we’d love to talk!