In our last blog readers learned how simulation is revolutionizing the Pre-Development phase of the product design lifecycle. Part Three: Make that Component Vehicle-Compatible explores how simulation can ensure that components will hold up against even the toughest conditions.

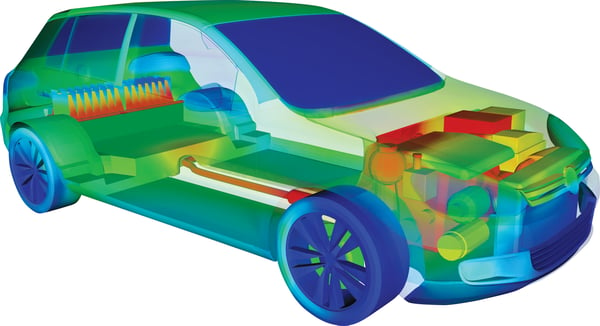

In the Development phase, OEMs are testing to make sure the automobile and integrated components will withstand various real-world environmental conditions. Designers are looking for endurance, reliability, predictability, repeatability.

Of course, to test a vehicle in the complete set of environmental conditions a car may encounter anywhere in the world, it must be exposed to very hot climates, extreme cold, rain, snow, varying solar loads, and so on. To test all of this with a built prototype, it’s not difficult to see how those costs add up in a hurry. Is it necessary to travel a built prototype across the globe, from Saudi Arabia to Switzerland, to learn how that car will withstand every climate literally under the sun?

Again, simulation to the rescue. To test a heat shield in a given component or compartment, it is entirely possible to accurately simulate the full spectrum of environmental condition sets. It is further possible to do so by testing dynamic — or transient — driving cycles, so that you’re not simply testing steady-state, “worst-case” scenarios. This had been the standard process until simulation technology matured to the point it has today.

Sure, you are likely to have issues arise, such as thermal management issues. But wouldn’t you rather find these in the virtual realm before you go to the time and expense of building and globetrotting the physical prototype? Furthermore, the simulation technology will precisely pinpoint the exact location and specific nature of the thermal issue, removing the guesswork and re-testing that has been common and costly for so long when relying on track testing alone.

Our final blog, Validation: Accounting for Variants, is coming up. Stay tuned as we explore how you can implement simulation into your design process, saving valuable time, money and resources!

Learn more about our transient thermal simulation TAITherm on our website.