Before you could return to the car, the afternoon rainstorm rolled in and started to downpour. Racing your vehicle, you jump in; your raincoat is soaked through. After relishing the reprieve of being safe from dive-bombing raindrops, you start your car and turn up the heat.

As the minutes pass and the vehicle cabin begins to warm, your coat dries out, and you go from shivering to just plain cold. After a few more minutes, your coat is dry, and you begin to feel warm again.

You may have noticed there are varied thermal behaviors taking place in this scene.

Thermal Implications of the Wet Rain Coat

When the jacket is wet, the thermal and evaporative resistance of the garment can be reduced. This means that the person will begin to feel cold as the moisture evaporates more quickly and draws more energy (heat) away from the body. As the jacket dries, it begins to regain its thermal resistance.

Thermal Behaviors in the Vehicle Cabin

With the heat on, the cabin begins to warm. The rise in temperature creates a more comfortable environment for the occupant. The warmer temperature also introduces increased energy, which aids in the process of evaporation to help dry the coat.

Seek Solutions Efficiently

Both the clothing and automotive industries are seeking solutions to challenges like these, which require understanding the variables of complex thermal behaviors and interactions. The clothing industry is working to make advanced textiles that meet customer requirements. Customers are looking for waterproof, breathable materials and quick-drying (once the garment is over-taxed). Balancing these priorities can be challenging. Physically testing the clothing takes time and resources, not to mention there is a limit on the types of conditions designers can test.

The automotive industry seeks to generate a fast time-to-comfort while using energy efficiently. The challenges of designing for efficient energy use mean that manufacturers cannot only look at the cabin's temperature as a signifier of thermal comfort but also need to consider the problem holistically, including the moisture, alternative heating/cooling strategies, and preconditioning of the occupant.

Simulate the Entire Problem

Using TAITherm, designers and engineers can get a complete picture of the thermal interactions happening in any scenario and achieve a solution by simulating it with all its variables.

For the opening situation, you would create a human model and adorn it with the proper clothing materials. You can specify the clothing properties with values based on literature or your study. Then you would set the human model to use moisture transport for this system-level simulation instead of latent heat. Next, you would select the liquid-dependent material option in TAITherm, which allows you to specify a wet and dry thermal resistance.

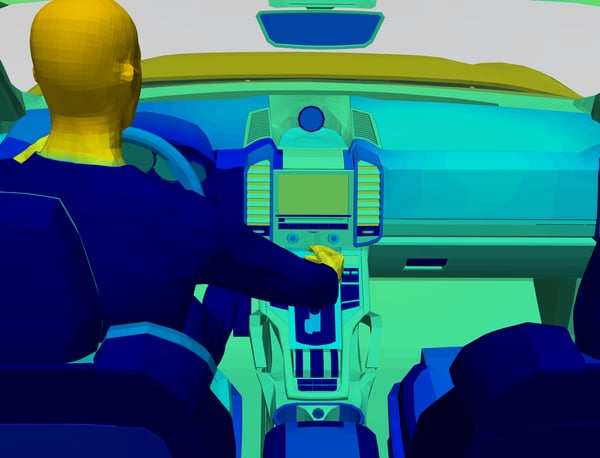

Next, you would create the environment for your human model. In this scenario, the human would be simulated in a vehicle with an HVAC system. You could also model different heating and cooling strategies such as radiant panels, heated/vented seats, or a heated steering wheel to see how they alter the time-to-comfort and energy expenditure.

When setting up the HVAC system in the vehicle, start by creating the fluid parts. Next, you would specify the airflow and imposed heat rates. The imposed heat would describe the nature of the air coming from the vents. This setup would model the initial cold cabin and the progression of the temperature change as the heater turns on, and the air warms. You would also need a curve that specifies the humidity in the cabin. With those two calculations in place, the model will track the amount of moisture in the clothing and predict the slow evaporation of the liquid. It will also predict the human temperatures during the transient analysis and thermal simulation.

When used in conjunction with the Berkeley Comfort Model (which is integrated within the Human Thermal Extension), you can also simulate the thermal comfort and sensation of the wearer and tailor your solution to reduce time-to-comfort.

Simulate All Variables and Advance Your Strategy

Moisture is an element that is often overlooked but that has a significant impact on human comfort. Both textile designers and automotive companies will benefit from adjusting their thermal simulation strategies to account for these critical variables. Simulating more scenarios and preconditioning simulations will help optimize designs for customer satisfaction.

If you want to learn more about using TAITherm to model moisture and its effects on thermal comfort, please feel free to request a live demo of our software.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: