Human and Environment Effects

Human and Environment EffectsEngineers, designers, and other stakeholders have been observing for decades the maturity of a potentially game-changing model for evaluating the effectiveness of systems designed to make car passengers more comfortable — and to do so more quickly and efficiently than ever before. This methodology, which analyzes and predicts physiology-based human thermal comfort metrics, has made significant advances against traditional methods (which measure environment-based comfort metrics), allowing designers not only to predict more accurate outcomes but to more reliably plan and design against them, saving significant cost and time in the process.

In With the New

Human Driving Thermal Analysis

Human Driving Thermal AnalysisAutomotive HVAC systems have done a fairly good job of adjusting a car cabin’s temperature. A passenger sets the climate control to 72 degrees; before long, the cabin’s temperature achieves or approximates the desired air temperature.

But what these systems have not historically accounted for is a predictive measurement of precisely how comfortable that passenger is in the cabin, as such systems have not been designed to account for a great many — yet critical — factors that contribute to, or work against, a passenger’s comfort level.

Until now.

As recently as 2009, a new approach known as the Berkley Comfort Model was published that explicitly accounts for physiology-based metrics in predicting passenger comfort. This approach measures and accounts for the physiological response to environmental factors and factors in a wide range of initial conditions that traditional methodology overlooked.

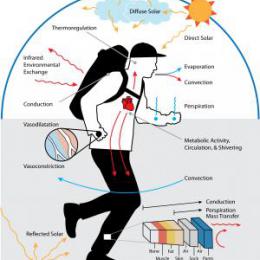

Scientific testing and modeling have been published to demonstrate how this advancement in how one measures passenger comfort can dramatically impact results. Interestingly, the results of such tests validate and illustrate just how reliable comfort measuring and predicting can become using analytic tools that can account for factors such as metabolic heating, shivering, respiration, blood vessel dilation or constriction, perspiration, clothing factors, and even the passenger’s activity level just before entering the vehicle.

In fact, this recent study showed that time to comfort could vary by almost a factor of two, depending on a passenger’s pre-cool-down activity, which alone demonstrates the disparity between measuring environmental metrics only as opposed to physiology-based comfort metrics.

In other words, getting that passenger comfortable can be entirely different than simply getting the cabin to a 72-degree temperature reading. It may take longer or shorter…it may require more energy, and it may require less.

But comfort is truly what the passenger wants. And knowing how best to achieve it is what designers and engineers need to know.

Cutting Time and Costs Through Virtual Prototyping

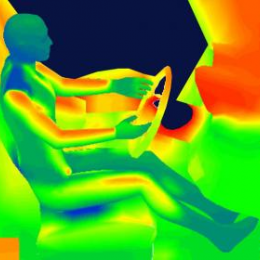

What this means to designers and engineers is significant. Teams can use such analytics to more accurately assess the efficacy of existing or planned HVAC systems and use these simulation tools for pre-testing during the design phase.

The power to predict and analyze creates a scenario where “virtual prototyping” can be completed. In essence, a design team now has the ability to place a virtual human into a cabin to monitor skin temperatures and accurately predict comfort levels and use this more reliable data to make important design decisions. Rather than building a prototype and testing it, then repeating as necessary until it’s right, modeling & simulation is all done during the design phase, with the potential to dramatically reduce concept-to-completion times…and to realize significant financial savings as a result.

The methodology for predicting passenger comfort has matured, and the tools to analyze and evaluate it have greatly advanced in only a few short years. The data available to design teams has never been more reliable, enabling automotive manufacturers to more efficiently and completely comfort passengers than ever before.

More importantly, these analytical tools eliminate potentially multiple phases of costly and time-intensive prototyping simply by replicating and accounting for the human element's most critical scientific input.

Learn more information about ThermoAnalytics’ Human Thermal Extension for the proprietary TAITherm Thermal Management software on our website.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: