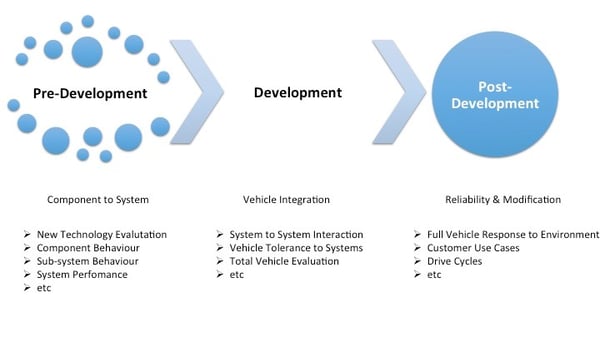

This blog series has discussed the benefits of simulation in every phase of the product design cycle. Part 4: Validation - Accounting for Variants examines the use of simulation in ensuring that the product design is accurate and reliable. Validation, the final step in the product design cycle, is a crucial final step in the entire process.

Ultimately, once all of the issues and eventualities have been identified and accounted for through simulation, the physical test is used only for validation or final sign-off. You’re actually getting to validation sooner as it’s far easier and vastly quicker to adjust a simulation model than it is to rebuild a prototype.

But even in the Validation phase, simulation is being relied upon to save time and costs. Though the production model has now proven reliable in the first two phases, the OEM must now consider variants to the design: perhaps the designers want to change some packaging, or aesthetics; or the new model is integrating a different exhaust system; or now the OEM has to consider trim level options (e.g. larger engine, different interior materials, or a “fancier” grill). This is also when market-specific alterations are made — making that same vehicle compliant to varying standards in, say, the U.S., European, and Saudi markets.

Because of its flexibility, simulation can do that too. When working in the virtual realm, the “options” are literally endless. In the physical world, conversely, addressing new issues that arise this late in the validation game are costly, as you’re so far down the proverbial road by now. In reality, there are some thermal issues that you simply can’t predict once options are implemented. Simulation software (like TAITherm) allows the design team to visualize hot spots, select a component that is causing thermal issues, and enabling one to simulate the problem. This allows one to correctly identify a problem and quickly solve it — without physically building every imaginable variant to the design model that will eventually hit the road.

This is also where on-road testing can realize the most precise and efficient returns. If you have not tested market-specific conditions and regulatory conditions in the development phase, you may incur costly “call-backs” that necessitate the vehicle go back to the test track. Simulation can avoid such scenarios by accounting for them early in the process, by replicating real-world conditions…as opposed to the theoretical worse-case scenarios and standards.

Returning to Return…

In the end, it is all about reducing time, reducing cost and getting that return on investment to happen quicker and more efficiently than ever. To achieve this, what is required is robust technology, advanced methodology, and an optimized set of intelligent, sophisticated tools.

With these intelligent tools in hand, the next time someone offers you a choice between speed, precision, and affordability, you can choose all three!

Learn more about our transient thermal simulation TAITherm on our website.