Introduction:

Joule heating, also known as Ohmic or resistive heating, is produced when an electric current passes through an electrical conductor. The most common applications of Joule heating are for conducting electricity, generating heat, or regulating current for power electronics. Modeling Joule heating is essential for electric/hybrid electric vehicle (xEV) components and many other applications involving an electrical source and conductive materials. The Joule heating model in TAITherm calculates localized heating when a current or voltage source is applied to a part of the shell or solid elements.

A few xEV examples are battery cell tabs, bus bars, wiring harnesses, fast charger connections/wiring, electronic circuits such as inverters, rotor windings in electric motors, radiative heaters for human thermal comfort regulation, and positive temperature coefficient heaters for heating, cooling, and ventilation applications. Other examples include catalyst heaters for exhaust applications, resistive elements in windshields for de-fogging and de-icing, heated clothing (vests, socks, gloves, etc.), heated seats, and heating elements in general.

Methodology:

Heat generation depends on electrical resistance and current. Resistance is a function of resistivity, cross-sectional area, and length. While simplified models exist, bus bars and electrical connectors often have variable cross-sectional sizes and shapes. Resistivity is also a function of temperature, requiring temperature-dependent heating from a coupled Multiphysics approach. The TAITherm model is a three-dimensional Multiphysics solution with temperature-dependent heat rates, which can be used with parts with varying thickness and arbitrary geometry. The conduction of electricity is characterized in TAITherm using the inverse of electrical resistivity, known as electrical conductivity, an intrinsic property independent of part shapes and sizes. Specifying electrical conductivity allows users to arbitrarily define the geometry without simplifying assumptions such as equivalent cross-sectional areas and equivalent lengths when parts have complicated shapes and sizes.

The Joule heating model in TAITherm requires only one geometry because it generates electrical nodes and solves them in a solution matrix analogous to the thermal solution. The electrical nodes use voltage instead of temperature, and heating is calculated as the square of the voltage difference between nodes times the material’s electrical conductivity at a specific temperature. The temperatures are retrieved from the thermal nodes in the same element. This streamlined approach provides a simple and user-friendly experience when setting up models in thermal and electrical domains. The Joule heating model supports multiple connected parts using a continuous mesh, including shell and solid elements. The contact resistance between components can be specified to achieve localized contact heating, which is automatically applied to the thermal nodes that are directly connected in adjacent parts. Multiple electrical parts are supported, with many electrical source/sink definitions, to achieve realistic electrical circuits.

The model can be used in conjunction with any other electrical models in TAITherm, such as batteries, motors, and power electronics. Both thermal and electrical material properties can be expressed as either scalars or curves, as can the electrical boundary conditions of applied current or applied voltage. Electrical parts can have non-electrically conductive coatings to represent insulation outside the conducting elements, and those layers are ignored in the electrical solution. Temperature limits can be applied for the interpolation/extrapolation of electrical parameters to aid in model convergence, and initial solver settings can also be applied for improved convergence. Contacts between parts can be automatically generated using a default electrical conductivity or directly specified to apply different contact resistances to other connections.

Case Study:

The Joule heating model has been validated using multiple geometries and electrical source types. Several proof-of-concept case studies have been prepared to illustrate the practical uses of the model. These case studies include battery pack bus bars, inverters, heated seats, exhaust catalyst heaters, and fast charger connection cables. Both steady-state and transient cases have been run with varying thermal and electrical boundary conditions to highlight some of the features that are included in the model.

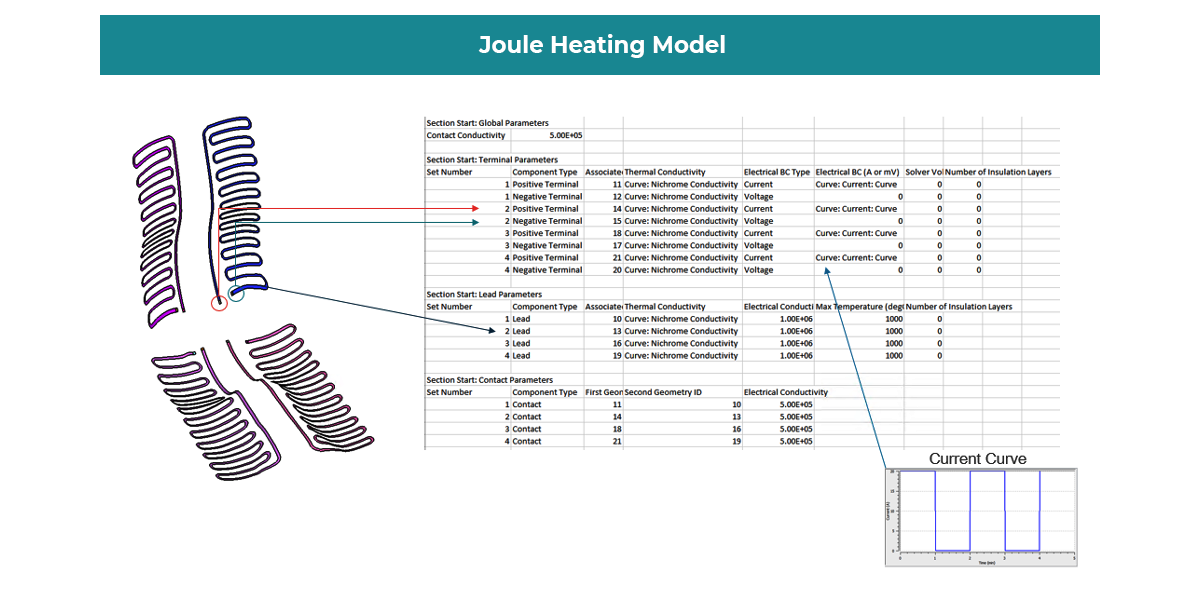

A case study of a heated seat will be reviewed and illustrates the usefulness of this innovative model. First, a brief look at the set-up of this model. The electrical setup is shown below, where a current curve is applied to the seat heater geometry. Each heater has a positive and negative terminal and at least one lead. An oscillating current input was used to keep the seat from getting too warm for an occupant.

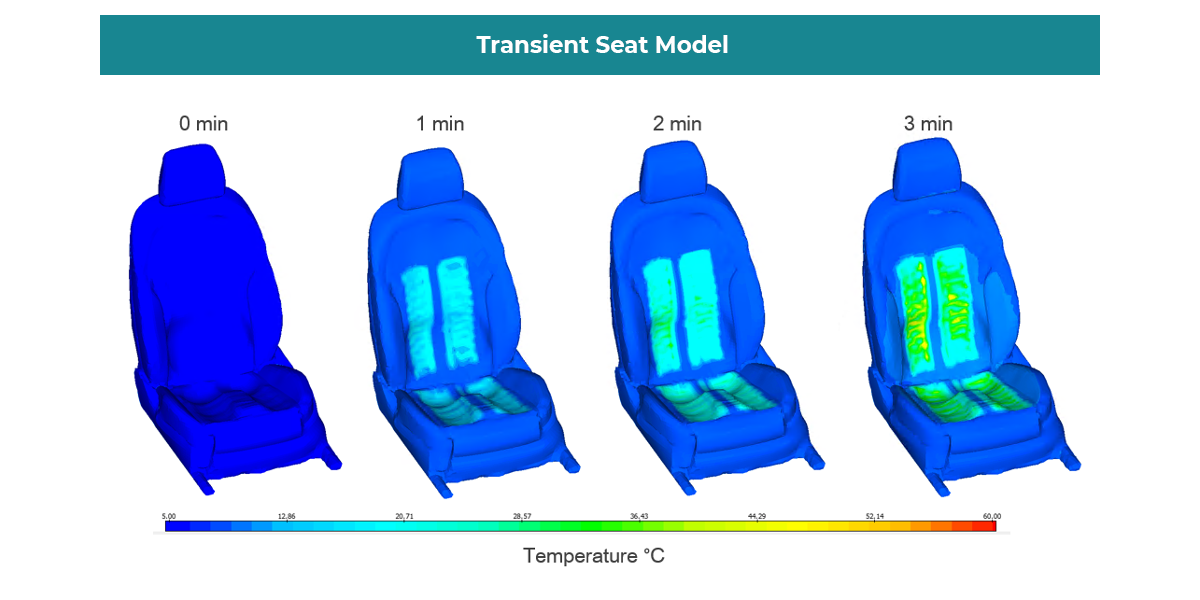

The seat model is a transient model that runs for a duration of 4 minutes. The model starts at a cold condition of 5°C and then heats up. The transient temperature behavior of the model is shown below.

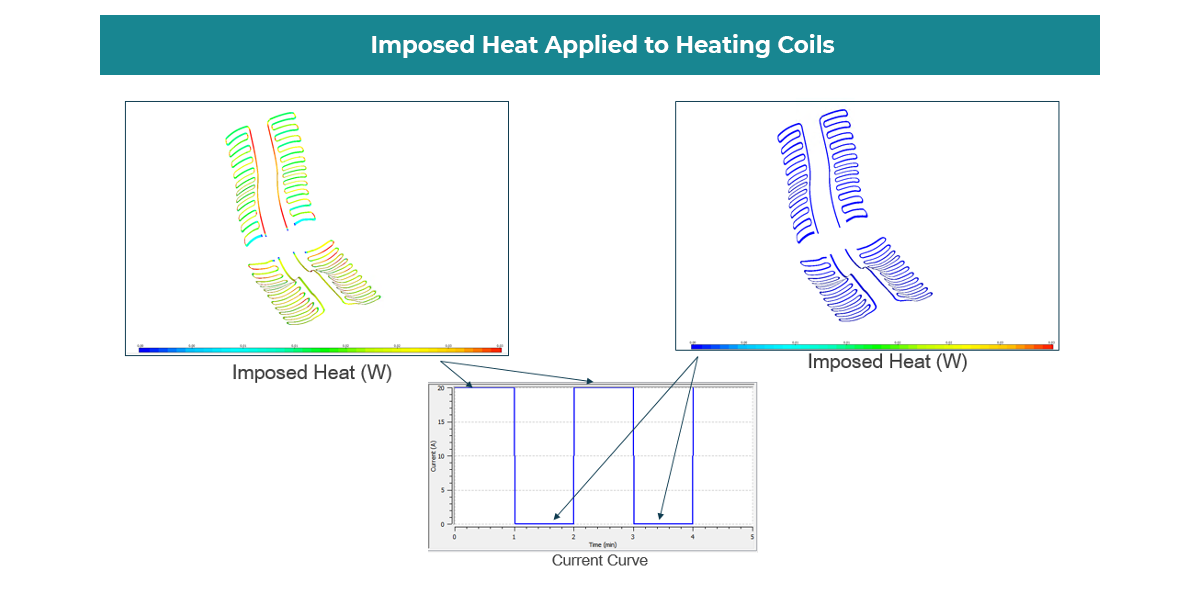

The heat applied to the seater coils comes from the Joule heating module. The script applies an imposed heat on the electrical components, as shown below. Since a curve input is used, we have times in the model where the imposed heat is being applied and times in the model where no imposed heat is applied because the current is 0.

Using the Joule Heating Module with a heated seat allows a designer to quickly change boundary conditions and evaluate different seat designs. This application could also be further extended to include the Human Thermal Module to add comfort predictions to the simulation. Using the Joule Heating Module with a heated seat allows a designer to quickly change boundary conditions and evaluate different seat designs. This application could also be further extended to include the Human Thermal Module to add comfort predictions to the simulation.

Conclusion:

The Joule heating model in TAITherm can model almost any type of electrical connector and can accommodate 3D geometry with varying cross-sections and shapes. It has been validated considering several different setup variations, such as solid vs. shell elements, quad vs. tria, current source vs. voltage source, coarse vs. dense mesh, and temperature-dependent conductivity vs. scalars (in thermal and electrical domains). The Multiphysics approach taken here can be combined with several other electrification models in TAITherm and can be used for a more comprehensive thermal analysis when temperature-dependent heat rates are important. Taking advantage of TAITherm’s usability and speed, the Joule heating model can be incorporated into full-vehicle models and consider a wide range of simulation conditions.

No matter where you are in your simulation journey, we are here to help you take the next step toward more advanced methods. If you want to take the next step toward modeling Joule heating with TAITherm, contact our technical sales team to discuss how the tool can advance your project.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: