A critical aspect of engineering for complex systems is managing designs that must perform under a wide range of combined parameters. An example is designing an electric passenger vehicle’s climate control system. Here we illustrate a state-of-the-art system-level simulation method that vehicle manufacturers employ to maximize their electric vehicle range while keeping customers satisfied with thermal comfort. We explore in this article the past benchmark convection methods of thermal management, challenge that approach with a radiant alternative, and estimate the impact on the EV range.

Virtual Development: Simulating Electric Vehicle Comfort

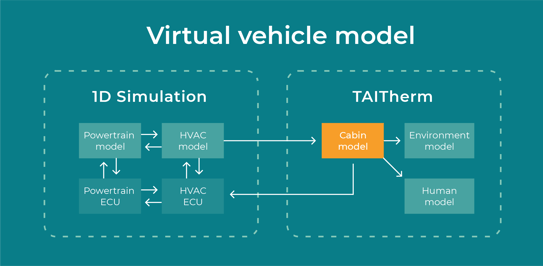

As lower-density batteries replace high-energy-density fuel, waste heat traditionally harvested from the engine cooling jacket for cabin heating is now a direct cost to vehicle range performance. Thermal comfort directly competes with range for the same limited energy source. As such, the engineering payback is substantial for designing across many climates and driving scenarios while finding innovative ways to minimize battery load. The- state-of-the-art is to couple 1D system tools with TAITherm’s 3D thermal software solution: it is the fastest, most complete, and most flexible means of realizing tangible reductions in load while sustaining (or improving) thermal comfort. Engineers can only enhance a design when they have a tool to rapidly evaluate its key performance factors and trade-offs for the consumer. TAITherm is that tool, partnering with established 1D protocols, resulting in unmatched speed and accuracy.

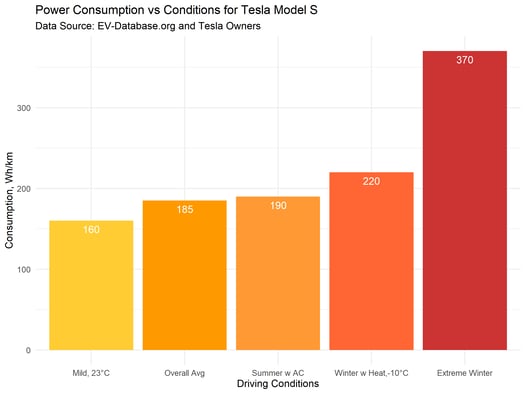

Figure 1. Effect of environmental temperature on total energy consumption of a Tesla EV per kilometer of travel.

Optimizing Thermal Management Solutions

Before we begin, let’s do a reality check: do we really need to solve this problem? YES. All caps mean there is no debate here: heating and AC loads routinely exceed 30% of an EV’s energy budget and can double the baseline mild environment battery load in extremely cold climates. The Tesla Model S has a 95kWh useable battery capacity. The range in mild weather is about 585 km, but that drops to 430km mixed city-highway at -10°C, according to EV-Database.org, as shown in Figure 1, and a reported value in extreme Canadian winter from owner comments on this page that is likely reflects using the full 6kW electric heater value of a Model S.

Understanding Energy & Power Consumption

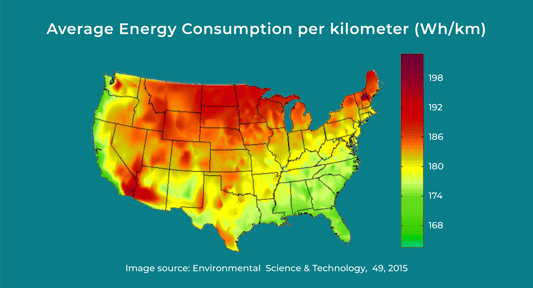

Is EV range a widespread concern? Yes, over much of the US and other temperate zones worldwide. For example, Nissan Leaf vehicles were surveyed to determine their energy consumption per mile throughout the continental US. Figure 2, published by Environmental Science and Technology, shows the geographic variance of this consumption.

Figure 2. Average Energy Consumption per kilometer (Wh/km) averaged across a fleet of Nissan Leaf EVs over a year. Image source: Environmental Science & Technology, 49, 2015

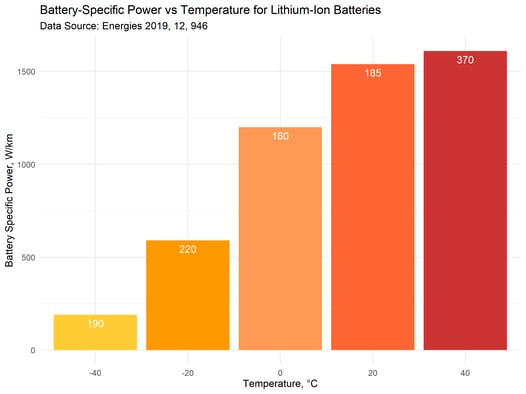

Beyond the load impact of cabin thermal management in cold weather, there is also a supply impact: the battery-specific power varies with temperature in a way that compounds the issue. For Li-ion batteries, the plot below conveys the extreme drop-off in capacity at lower temperatures, amplifying the importance of cabin energy management even higher.

Figure 3. Temperature impact on battery-specific power for lithium-ion batteries. Data Source: Energies 2019, 12, 946

The Energy Effectiveness Challenge: Panels vs. Puffs

Our analysis will see if electric heating panels can maintain thermal comfort while reducing heated airflow during cold startup. Will the panels beat the puffs and give our EV added miles? Or do we double down on hot air? Place your bets. Oh, and we won’t need a hundred CPUs. A laptop will be just fine.

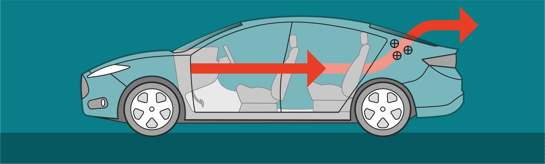

Figure 4. The ‘Puff’ solution – convective heat delivery to warm the cabin, with high volume flow into the cabin and exiting through ports near the vehicle's back.

Figure 5. The ‘Panel’ solution – reduced convective flow plus localized warming of the seat, steering wheel, and radiant panels.

Raising Expectations through Virtual Development

Traditional heating methods did not require as many engineering scenarios because the “cost” of the heat for comfort was comparatively low. High-resolution CFD was often employed, running only a few scenarios due to the extreme computation time of transient scenarios. But EV users expect performance, as new EVs often target premium buyers. Such consumers take a dim view of a substantially reduced range for EVs, listing range anxiety as a primary barrier to EV adoption. Thus engineers need to innovate through this challenge. And to innovate, they need a more rapid means of evaluating system-level performance, accurate human thermal comfort simulation, and transient analysis for a wide range of climates.

Fast Turnaround & Connected Power

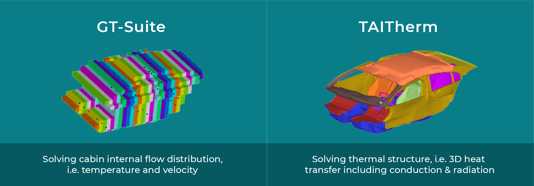

A strong example of TAITherm steady-state coupling is linking with the 1D modeling tool GT-Suite. TAITherm handles the complex heat transfer physics and vehicle cabin surface temperature distribution, while GT-Suite handles the wider 1D-system loads on the battery and provides a moderately dense volume mesh for cabin HVAC flow. This moderate-fidelity airflow, combined with TAITherm’s environmental, solar, and human models, enables rapid transient analysis on a desktop (faster than real-time) and permits the wide range of drive cycles and operating parameters that engineers need to comprehensively profile system performance across global markets.

Figure 6. Virtual vehicle model systems simulated by 1D Analysis coupled with TAITherm 3D thermal simulation.

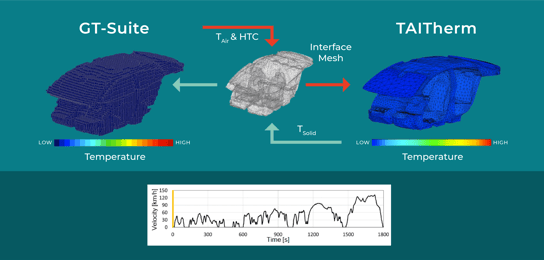

As shown in Figure 7, GT-Suite’s voxel-based fluid nodes handle the airflow from louvers to vents, and TAITherm maps these fluid node flow rates and temperatures to the surfaces of seats passengers, and cabin, resulting in a data exchange at each iteration. This well-structured paradigm rapidly converges and provides 2X real-time computational performance for transient drive cycles on a desktop PC.

Figure 7. 1D Voxel mesh used in GT-SUITE and surface mesh employed by TAITherm for vehicle cabin modeling and load estimation during transient cold weather driving.

Exchange is facilitated using an interface mesh as shown in Figure 8, that couples the fluid volume nodes with the cabin surfaces nodes, with data exchanged each iteration for a coupled convergence.

Figure 8. Data exchange with interface mesh between GT-SUITE and TAITherm for transient thermal simulation.

Virtual Thermal Management - Indoors or Out

Because TAITherm supports drive cycles based on proving ground realities, engineers can now virtually prototype and virtually validate their designs as they would on a physical prototype in Arizona or northern Canada. In many cases, an engineer may wish to validate against a climatic chamber. TAITherm does that, too, even faster because the sun doesn’t move around in an environmental chamber. Thus no matter what your engineers face invalidating their thermal performance, TAITherm delivers fast results and plays nice with partners like 1D tools CFD and FEA codes for stress/strain.

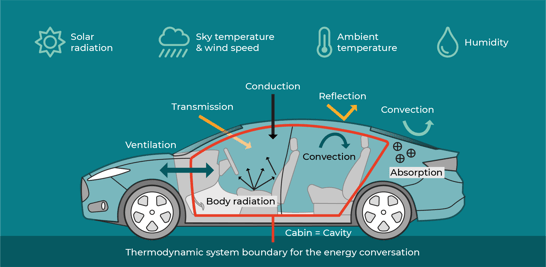

Figure 9. The TAITherm energy balance for cabin climate modeling.

Measured Energy Effectiveness - Radiance VS Bulk Air

Our first model consists of a baseline warm airflow that begins at an ambient of -10°C with a combined fan and heating element load of 3370W. However, the maximum power for electric HVAC heating is reportedly 6kW for a Tesla, and BorgWarner recently deployed a commercial heating module with 7kW max output.

Figure 10. Radiant Panel locations for feet and legs.

Figure 11. The heated seat and steering wheel are conductive solutions to thermal comfort.

The challenger to this traditional method is to reduce the airflow load by 80% resulting in 600W convective delivery while imposing 42W to the steering wheel, 66W to the driver seat, 75 W to overhead panels, and 160 to radiant panels near the feet. The total battery load is thus about 940W.

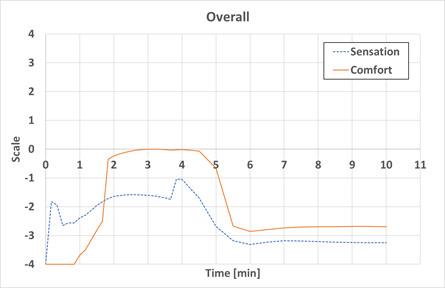

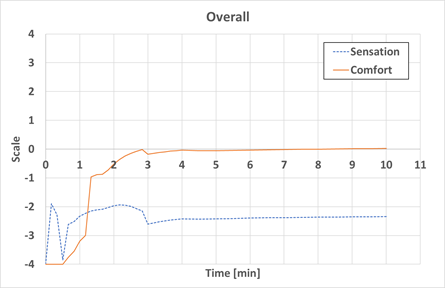

A comparison of the results of these two models is found below. In Figure 12 we see that thermal comfort takes about 2 minutes to establish, but as time bears on, the comfort drops with deeper overall thermal sensation. Figure 13 shows the radiant solution is more responsive, establishing initial comfort sooner and holding stable over time.

Figure 12. EV driver thermal sensation and comfort for the traditional convection only heating scenario.

Figure 13. The EV driver’s thermal response to the reduced convection, radiant panel scenario.

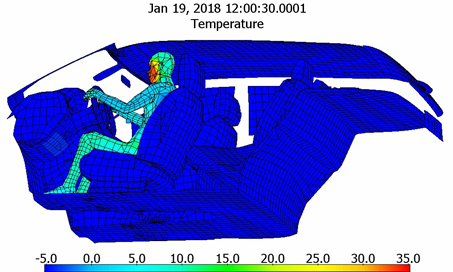

Figure 14. Human thermal model positioned as the driver in an electric vehicle in the TAITherm graphical user interface, with results showing surface (clothing) temperatures at the start of the simulation.

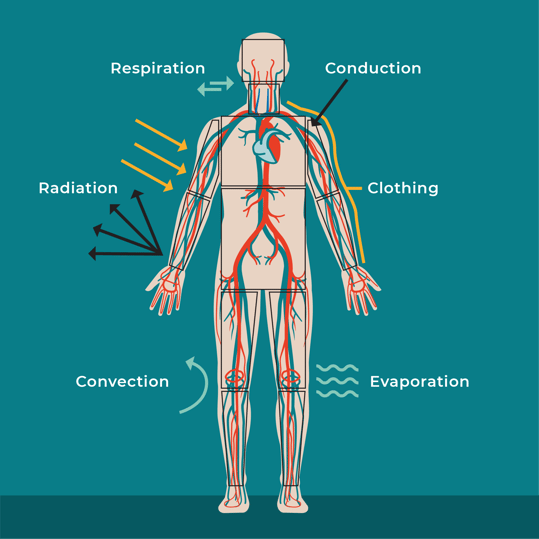

Evaluation of the effectiveness of each cabin heating method is determined using ThermoAnalytics’ state-of-the-art Human Thermal Model. It is fair to ask the question at this point, “Is such a sophisticated simulation method necessary to evaluate vehicle engineering – can we not just use average environmental temperature to predict human sensation?” The short answer is that human physiology is a complex adaptive system, and grossly simplified methods will fail to predict the response of test subjects exposed to distributed temperature environments, especially under transient conditions: see Figure 15 for an overview of the virtual human energy pathways. Human thermal sensation is based on the temperature distribution throughout the human body, with our model including complex weighting and factors for the thermal ‘history’ – what the body was experiencing in previous time steps. Designing an optimal climate control system is thus dependent on an accurate outcome metric: accurate thermal signature predictions of sensation and comfort over time.

Figure 15. The ThermoAnalytics Human Comfort Model – the global benchmark for accurately simulating human thermal physiology, sensation, and comfort, used in this example to evaluate the efficacy of convective cabin heating vs targeted radiant panels.

Human-Centric Approach to Energy Management

The panels rise in temperature quickly, resulting in a more rapid stabilization of the driver's thermal comfort. Because a single person drives most vehicles, this is the most common scenario for engineering. However, the bulk air method provides heating to the entire EV cabin, which is a drawback (it is usually unnecessary) but means that the range does not change much if there are three more passengers. So it stabilizes the range expectations to a lower level, though the University of Michigan reports that in 2017 US vehicles averaged only 1.5 persons per vehicle.

The radiant method of EV thermal management is thus scalable – meaning the power load to achieve comfort is reduced for the typical situations of one or two occupants, with decreasing range as more radiant panels are powered up. For a single passenger, the convection dominant case 1650-470 = 1180 Wh more energy over an 1800 second drive cycle. The total power load for a Tesla Model S running convection heavy would go from about 16kw to 19.4kW, yielding a range drop from 600km to 490km. In the extreme cold, with the 6kw heater maxed out, the range is only 430km. These are just based on load and ignore the reduced battery capacity when it is cold at startup.

The same Tesla, modified to use the radiant solution, would yield a range of about 70km greater than the convection-only approach. The bottom line is that the radiant panels require an overall one-third less hotel power for an EV, resulting in a 14% higher range. This performance improvement can be evaluated early in the design cycle and virtually validated using TAITherm partnered with 1-D analysis tools. With control scripts, EV drivers' tendency to adjust HVAC temperature and flow over time can be easily accommodated in TAITherm when using a virtual human model, so this method is highly extensible and capable of incorporating human and electronic feedback loops.

Utilizing this method in Other EV Design Applications

Coupled system-level simulation running at 2X real-time allows engineers to examine realistic system behaviors and their transient impacts on EV battery range. Beyond optimizing climate control, lightweight components and materials can be evaluated for thermal performance and durability. IP cluster elements can also be assessed this way, enabling more design iterations than possible with CFD analyses alone. Rapid virtual engineering drives successful product development at many automotive OEMs and Tier 1s; TAITherm’s performance with 1D tools has emerged as the leading methodology that ensures optimal thermal performance with minimal battery load. Contact us to discuss your application with a thermal analyst: qualified organizations can receive a full briefing on best practices for incorporating this method.

If you want to learn more about using TAITherm to maximize your EV range in cold-weather environments, please feel free to request a live demo of our software.

Visit our website at suppport.thermoanalytics.com for

- FAQs

- Webinars

- Tutorials

Get help from our technical support team: